.png)

.png)

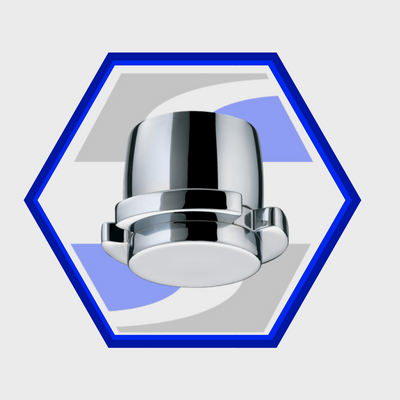

One of the most common enquiries we receive at Silchrome is that of repairing worn/damaged chromed items which can include anything from car bumpers through to bathroom fittings. Here is an overview on what issues re-plating can solve and potential costs.

What Issues Can Re-PlatingRead more

.png)

.png)

Zinc Electroplating offers a low cost but highly effective way in which to protect ferrous metals against a range of Corrosion sources. So what is Zinc, what can it be used for?

What is Zinc?

Zinc is a naturally occurring element that is abundant in the earth’s crust and is

Read more

.png)

.png)

Silchrome Plating are pleased to announce the further expansion of our team with a Graduate Vacancy for a Chemist.

Company Overview:

Silchrome Plating are a thriving metal finishing business in Leeds, West Yorkshire. Established for over 60 years with a strong reputation in the

Read more

.png)

.png)

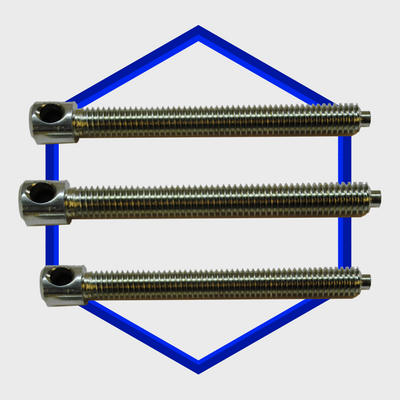

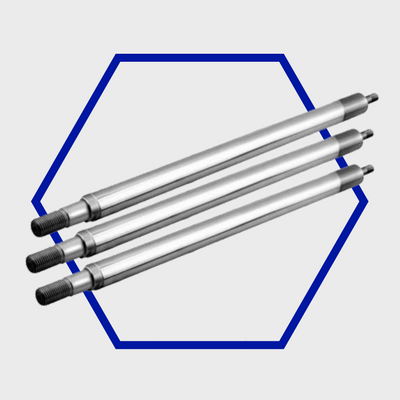

Hard Chrome Plating is a metal finishing process most often selected for high wear applications, although it is often described as having a ‘good’ resistance to corrosion, what factors would Hard Chrome protect against and what are its weaknesses?

What Is Hard Chrome Plating?

.png)

It is often confusing how one element can have several different plating methods, often sharing a similar name but intended for different purposes. That is certainly the case for Nickel which has a number of distinctly different processes. Nickel Plating is often specified to further enhance a

Read more

.png)

.png)

We recently were asked by a customer for what options were available for achieving a Gold finish on his components. In this particular case the end application was a single large item and the finish needed to be decorative rather than functional, here are a few options...

Gold

Read more

.png)

.png)

Silchrome Plating are currently looking to recruit: A Process Worker, Paint Sprayer and Lab Technician...descriptions below!

About Us: Silchrome Plating are a thriving metal finishing business in Leeds, West Yorkshire. Established for over 60 years with a strong reputation in the sector, we

Read more

.png)

.png)

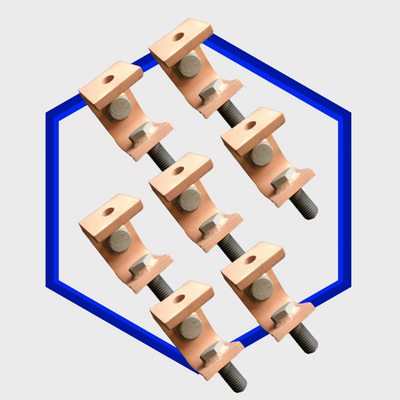

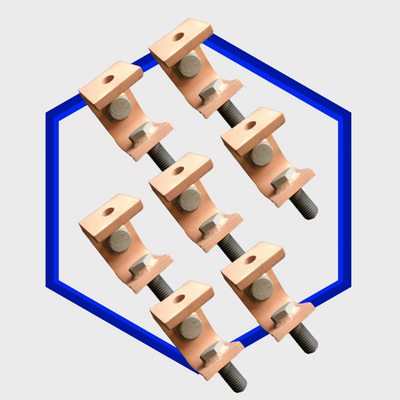

Silchrome Plating always endeavour to process our customer’s parts in the most cost effective manner that will achieve the desired specification. You may have heard about Barrel, Rack and Jigging when talking with us about finishing your parts, but what does those terms mean?

BarrelRead more

.png)

.png)

Silchrome Plating has been providing metal finishing services for over 60 years and we wanted to look over the history and changes to the metal finishing industry.

Origins

The invention of electro-plating can be attributed to Italian Chemist Luigi V. Brugnatello

Read more

.png)

.png)

In order to provide our customers with the most accurate quotation it is vital to give us as much information as possible, these are many different factors that can affect both the turnaround and cost of your jobs so having accurate information is essential.

Metal Finishing Information

1.

Read more

.png)

.png)

Silchrome have a comprehensive guide to Electroless Nickel including it's attributes and applications.

ENP is a very versatile process that can add corrosion resistance to a variety of components, by changing the Phosphorus content you can better adapt the process to your appllication

Read more

.png)

.png)

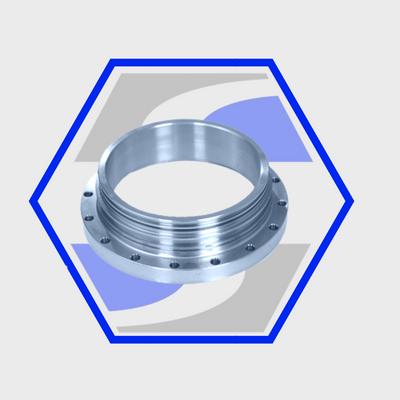

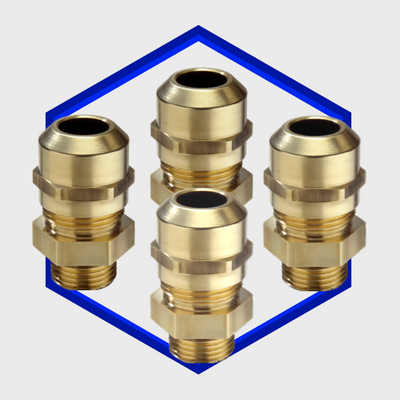

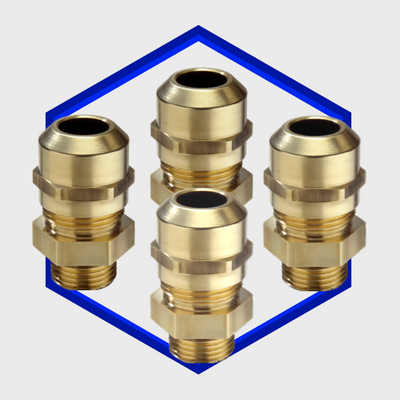

Electroless Nickel provides a uniform coating that will increase wear and corrosion resistance of Brass, Aluminium and Steel components. The versatility of the process and the ability to change the phosphorus content to suit your application makes Electroless Nickel a popular process

Read more

.png)

.png)

How do Silchrome ensure a consistent and high quality finish for your components? Here we explain some terms you may/may not be familiar with and explain why they are crucial parts of our process.

Activation

One of the most important steps in any plating or coating process is in the

Read more

.png)

.png)

Many different components are Zinc Plated in order to improve their part life and enhance their resistance to corrosion. The process, commonly referred to as just ‘Zinc Plating’ is actually short for ‘Zinc and Passivate’ so what exactly is Passivation and why is it needed?

Could You

Read more

.png)

.png)

Silchrome are known for our wide array of metal finishing processes, providing everything from copper plating, to chemical blacking. Alongside our various coating and plating processes we are also quite happy to provide associated services such as pickling and polishing.

Lacquer

When

Read more

.png)

.png)

Automotive companies have been refocusing on fresh, innovative ways in which to improve part life and performance. A large part of this work has been the introduction of new engines and new fuels and as such they have had to think of new ways to protect parts and increase life cycle. The

Read more

.png)

.png)

.png)

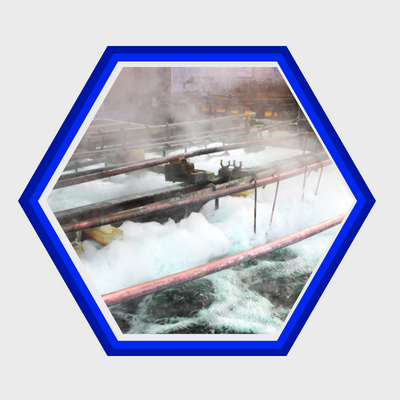

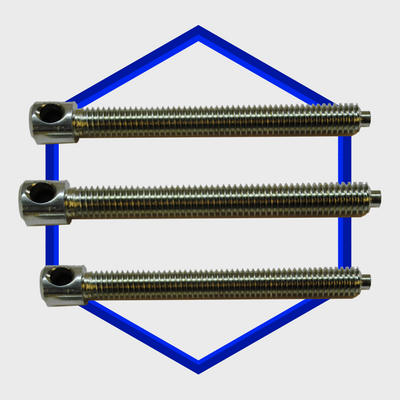

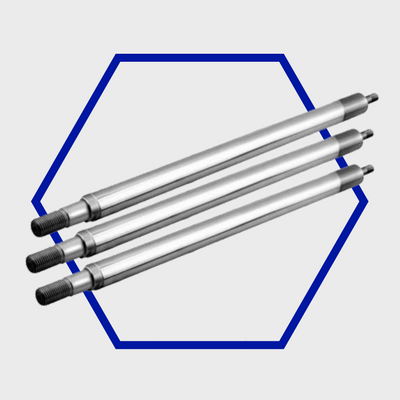

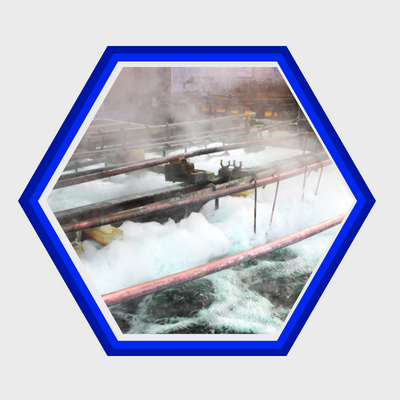

Electroless Nickel is widely used throughout the Oil and Gas Industry due to its uniform coating, excellent corrosion resistance and ability to act as a protective barrier against abrasion. There are three key areas in which Oil and Gas components must operate: Surface Operations, Downhole

Read more

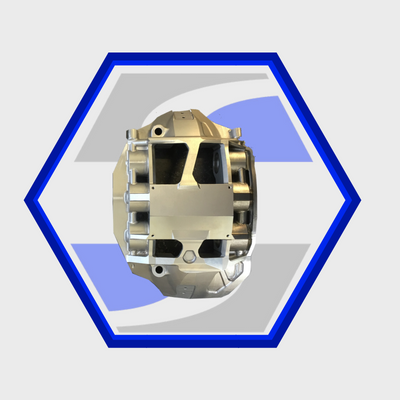

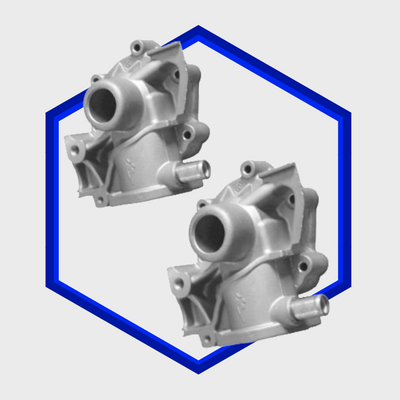

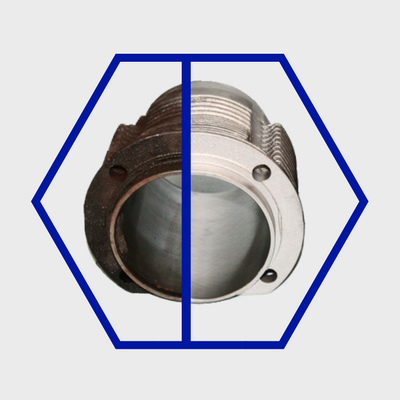

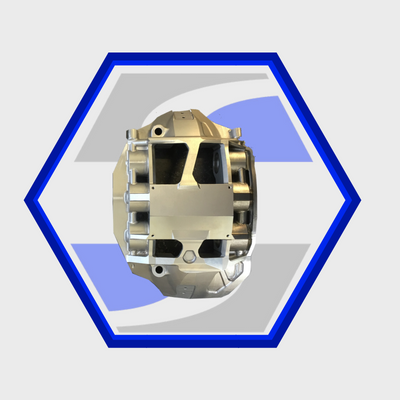

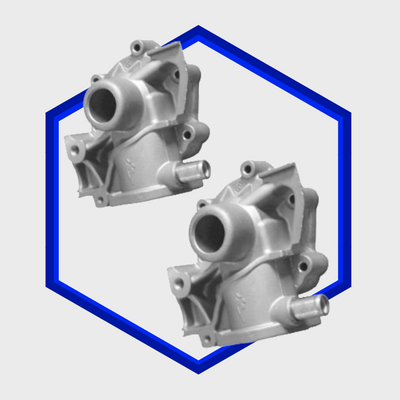

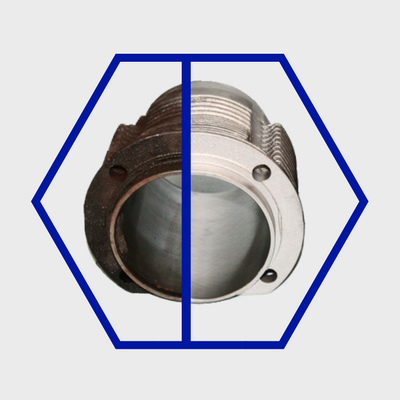

Cast parts represent a challenge to most metal finishing companies. Cast parts are prone to having rough surfaces of a non-homogenous nature and often contain a high carbon content, impurities and various residues. This means in order to ensure a high quality finish he right selection of

Read more

.png)

.png)

Silchrome Plating have invested heavily over the last four years allowing us to meet the high standards expected by our customers. Our focus is always to fast lead times, excellent service and high quality plating. We understand that as a company every member of our team needs to be

Read more

.png)

.png)

What is it?

Chemical Blacking is sometimes referred to as ‘Blackening’ or ‘Blackodising’and is a conversion coating meaning that where in other metal finishing processes a layer is added above the substrate, here a coating is achieved through a chemical reaction between the ferrous

Read more

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)