You asked: Gold Finishes

.png)

.png)

We recently were asked by a customer for what options were available for achieving a Gold finish on his components. In this particular case the end application was a single large item and the finish needed to be decorative rather than functional, here are a few options...

Gold Electro-Plating

The most obvious way to achieve a Gold like finish is of course by using the substance itself. Electro-plated Gold offers a high level of corrosion resistance, are electrically conductive and is disinclined to form an oxide layer, hence their popularity as a functional coating in the electronics industry. Nearly any metal can be Gold electro-plated although in many cases they will first undergo Copper Plating to ensure a smooth surface. The main disadvantage of Gold Plating is of course the cost of the raw materials makes it one of the more expensive options for metal finishing and here at Silchrome we only have an immersion tank available for this service. This means only small components can be processed, and only a nominal amount of Gold. Making this unsuitable for this customer.

Gold Passivates

Most often used in conjunction with Zinc Plating, a “Gold” Passivate is actually the same thing as a Yellow one. Traditionally the colour of the coating was an indication of the amount of Hexavalent Chromium in the makeup of the solution and the ‘stronger’ the colour the, higher the amount of Chromium and in theory, the better the performance. This may be the reason why many people specified Gold rather than Yellow. Although a Gold Passivate is certainly darker in tone than a Yellow, it is in no way reflective and smooth in the way that electroplated Gold would be. A casual observer would certainly not mistake a Gold Passivate for real Gold.

PVD

Not one to only talk about finishes we offer, PVD stands for Physical Vapor Deposition and describes a few different processes which are all achieved using some sort of vacuum chamber. Nitriding is one of the more popular. This can achieve a finish very similar to Gold, perhaps a little too light in tone depending on the base metal. The PVD process produces very hard wearing yet thin coatings but is only really suitable for smaller sized parts and becomes cost effective in larger batches making it unsuitable for our customer’s application.

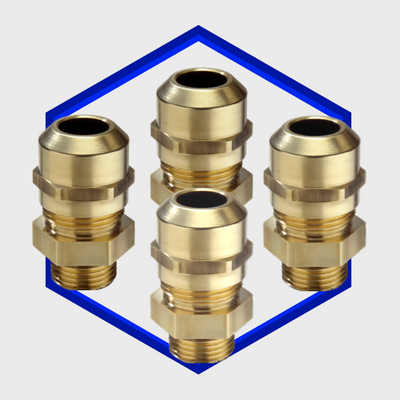

Brass Plating

Another option that Silchrome don't offer. Brass Plating is probably the closest visually you’ll get to Gold Plating and will also provide a good level of corrosion resistance and can actually be finished in a range of styles including Polished Brass, Antique Brass and a Satin/Brushed finish. Most often Brass Plating will be sealed with either a wax or a lacquer and this Lacquer in itself may be an option for a cost effective Gold Finish.

Lacquer

The term Lacquer covers a wide number of hard and shiny finishes and are similar in nature to varnish in that it helps to seal a finish from its environment, further improving its corrosion resistance. There are a wide range of different lacquers available and some can certainly provide a gold like finish.

Anodising

Aluminium components can undergo anodising which is a process which extends the naturally occurring oxide layer into a protective barrier. This layer is porous in nature and can be dyed to create a range of aesthetically appealing finishing which can include gold. An anodised finish will be less reflective than the actual metal, and will often appear almost plastic like to the casual eye.

As you can see, when it comes to metal finishing there is no such thing as a straight forward question. A simple request like a ‘Gold’ or ‘Black’ finish can have any number of different processes suitable, that’s why it’s important to give us as much information as possible about your component and its end application so we can point you in the right direction.