.png)

.png)

What is Electroless Nickel?

Electroless Nickel provides a uniform coating that will increase wear and corrosion resistance of Brass, Aluminium and Steel components.

Electroless Coatings are applied through an auto-catalytic technique meaning that a metal coating is formed through a chemical reaction. Electroless Nickel Plating forms a uniform coating, even on uneven surfaces and will increase wear and corrosion resistance of a component. It has a wide range of applications and is used throughout the Automotive, Oil & Gas and Petrochemical Industries. By changing the Phosphorus content, you can better suit Electroless Nickel to your application. Electroless Nickel meets ELV, WEEE and Rohss regulations.

What is the Process?

In Electroless Nickel Plating a component is immersed into a vat of plating solution. It’s a chemical process in which Nickel Ions are reduced using Sodium Hypophosphite which allows the Nickel to be deposited without the use of electric current. The Nickel itself acts as a catalyst for the plating reaction, and forms a deposit with a high degree of thickness uniformity over the entire component no matter its shape.

What are the Advantages?

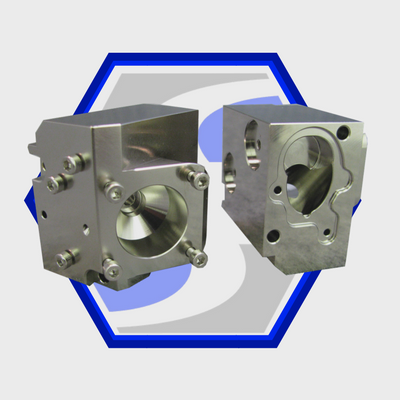

The main advantage of Electroless Nickel Plating is the uniformity of the coating which makes it an ideal process for components with intricate geometries and with a high number of holes, threading, cleavages and bends. ENP can also perform at high temperatures and it is this combination that makes it a popular process to offer protection for automotive components such as Carburettors, Engine Bearings, Pistons and Gears.

Electroless Nickel offers a high level of wear resistance most noticeably against fretting, erosion, surface fatigue and abrasive wear. Electroless Nickel can also be Heat Treated which will increase hardness and wear resistance to levels rivalling that of Hard Chrome. The combination of uniform coating and high hardness makes it suitable for surface operation parts in Oil &Gas such as Brake Assemblies, Gas Turbines, Heat Exchangers and Pump Housing.

Electroless Nickel has excellent corrosion resistance properties and can protect components against oxidation, sea water and petroleum. By varying the amount of Phosphorus content, Electroless Nickel can protect against different kinds of chemical corrosion. Low Phosphorus deposits (1-2%) perform better when dealing with Alkaline solutions such as Sodium Hydroxide. Medium Phosphorus deposits (7-9%) will perform similarly to Stainless Steel and can combat chemicals acidic in nature. High Phosphorus Deposits are better when dealing with acidic corrosion from chemicals such as Phosphoric Acid. High Phosphorus offer the best corrosion resistance against the widest range of sources.

What We Offer

Silchrome Offer Electroless Nickel Plating with both Medium and High Phosphorus content. We are able to carry out the process for components up to 1000mm x 600mm x 600mm and up to 100kg in weight.

You can find out more about our Plating Process HERE

Silchrome have also produced a comprehensive guide which you can download without sign up HERE.