Our Plating Process

.png)

.png)

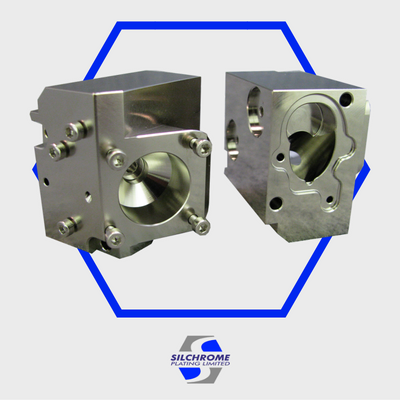

Silchrome pride ourselves on the care and attention we give to each and every customer which enables us to ensure a high quality coating first time and every time.

Initial Inspection

The start of the plating process is an inspection and contract review to ensure we fully understand your requirements. This includes a review of all technical specifications as well as ensuring we can meet your delivery needs.

Preparation & Pre-Treatments

Preparing the part for plating is a crucial step in our process. Depending on the material being coated a range of pre-treatments may be required. This could include physical preparation such as blasting or polishing and chemical pre-treatments such as cleaning and surface preparation. This preparation is often required to ensure effective bonding of the plating materials.

Plating

Silchrome have one of the largest arrays of plating processes in the UK, and everything is carried out in house in our production facility in Leeds. For many of our low volume orders, parts will be individually jigged on a manual line. For medium volume requirements we have a semi-automated line that can plate multiple jigged components. Silchrome can also accommodate high volumes of small components using our barrel line. Strict process control is maintained on all our plating solutions with our production team supported by dedicated quality personnel.

Post-Plating Finishing Processes

If required Silchrome is able to offer post-plating finishing processes. These are carried out in house to enable us to supply a fully finished product. Processes we can offer include passivation, polishing, painting and as well as some heat treatment processes.

Inspection

Before any components can leave our site, they must undergo full inspection to ensure quality standards have been met. Silchrome have a dedicated quality team and full in-house testing facilities which includes in-house X-Ray facility to enable precise coating thickness measurement. Silchrome are approved to ISO9001:2008 and the business also operates strict environmental controls and is accredited to ISO14001:2004.

Delivery

Once your parts have passed inspection and ready for delivery. The parts will be appropriately packaged to ensure protection and we will organise delivery. Silchrome have our own delivery vehicles and can offer both collection and delivery of parts if required.

Every step in this process ensures that Silchrome can provide the highest quality plating for your component. We can have an extensive range of finishing services including electroplating, conversion coatings, specialist spray coatings and painting. Contact us today to find out more.