What is Chrome Plating?

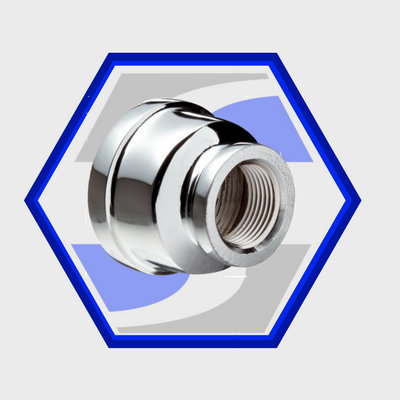

Chrome is a naturally occurring element, but is not useful in its raw form. Nothing is ever made out of solid Chromium, but it is electroplated onto different metals to provide either a decorative finish or increase the hardness and wear resistance of the base material. Many people will refer to any shiny metal finish as being Chrome, even where the element has not been used, but you can tell a genuine Chrome plated piece as the finish will be slightly blue in colour.

Chrome Plating falls into two distinct categories: Bright Chrome and Hard Chrome. The key difference being that Bright Chrome can be used for decorative purposes where Hard Chrome has more industrial applications.

What is the Process?

Chrome Plating is an electro-plating technique in which parts are placed into a vat containing an electrolytic solution and a current is run into the bath promoting the build-up of the material onto the component. With Bright Chrome plating a layer of Nickel is most often applied first, and then the chrome on top of this. In order to obtain the best possible results, parts will first be subject to a number of pre-treatments depending on their material which are all carried out in house.

What are the Advantages?

Chrome Plating produces a protective barrier for the part which offers significant improvements in protection against corrosion and rusting. Decorative Chrome will increase the Corrosion Resistance of the base metal, but not to the level of Hard Chrome Plating.

Chrome Plating produces a very durable finish which is what makes it so popular with the automotive industry. Chrome doesn’t oxidise or corrode and is able to withstand extreme temperatures as well as the weather. It will remain bright for a long time without the need for polishing.

Range of Finishes

Depending on your application, Chrome Plating can be finished in a range of decorative styles. These include ‘Bright’ or ‘Polished’ Chrome which will give your part a shiny and reflective surface that can be polished to provide a mirror finish. If a more textured surface is desired then we can provided Brushed or Satin finishing which will give your part a contemporary look. Silchrome also offer ‘Matte’ or ‘Dull’ finish which is non-reflective and used to be popular with motorcycle parts.

Specifications Offered:

AMS 2460, AMS 2406, and MIL-STD-1501.

What Silchrome Offer:

Silchrome can a full Chrome Plating service for both engineering applications as well as decorative. You can find out more information on our plating process HERE.

We also offer a full re-chroming service for parts like Car Bumpers. For these parts we often need to strip back the existing plating, polish out any scratches and bumps and then copper/nickel and chrome plate it in order to achieve a good finish. You can find out more HERE.

Silchrome offer a wide range of finishes including: Bright, Matte, Brushed & Satin

.png)

.png)