.png)

.png)

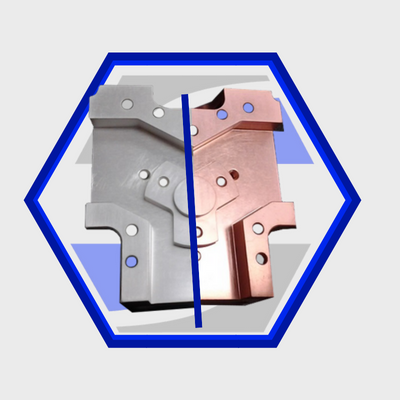

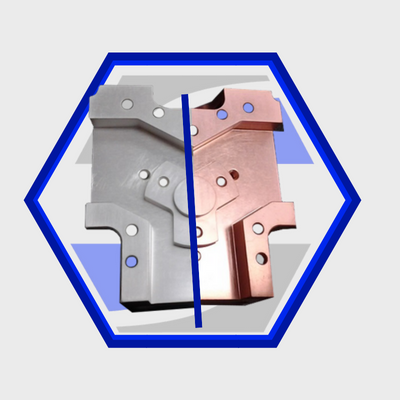

Metal finishing is the process of changing the surface of an object, for the purpose of improving its appearance and/or durability. It is a broad term that encompasses a wide range of different categories, techniques and processes.

The Metal Finishing field can be quite overwhelming for

Read more

.png)

.png)

Many of us may be familiar with the term ‘pickling’ as a way of preserving food. So how can metals be Pickled and what is the purpose and advantages of this process?

What Is Pickling?

Pickling is a cleaning process that removes impurities from ferrous metals. Ferrous Metals include

Read more

.png)

.png)

.png)

Restoring Chromed items is one of the most common jobs we are asked about here at Silchrome, we often receive enquiries from car enthusiasts looking to restore their pride and joy. Few people understand however that what we simply refer to as ‘Chrome Plating’ actually involves a number of

Read more

.png)

.png)

One of the most common enquiries we receive at Silchrome is that of repairing worn/damaged chromed items which can include anything from car bumpers through to bathroom fittings. Here is an overview on what issues re-plating can solve and potential costs.

What Issues Can Re-PlatingRead more

.png)

.png)

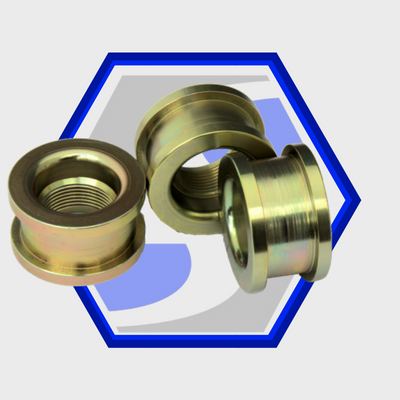

Here at Silchrome we are often asked the impact that a metal finishing process will have on the dimensional tolerance of a component. Here is a broad overview we hope will answer many of your questions.

Amount Added

Most metal finishing processes such as electro-plating or paint and

Read more

.png)

.png)

We sometimes get enquiries asking if it’s possible to anodise Carbon and Mild Steels. Most often this is being done for decorative rather protective reasons, with customers looking for a uniform and flake free coating. The short answer is that no, Silchrome cannot offer anodising on steels

Read more

.png)

.png)

.png)

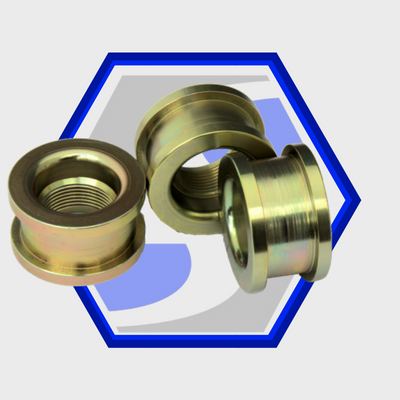

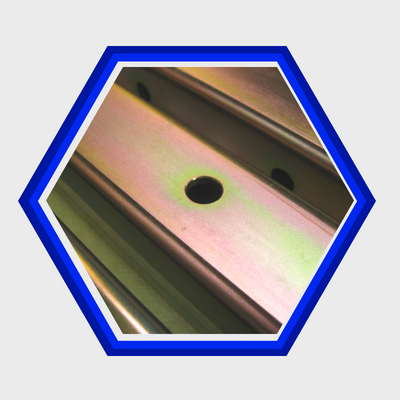

Zinc Plating is always accompanied by a Passivation process which will often have a colour associated with it. The difference between these colours and what exactly they are specifying can be a little confusing so here is a quick guide to some often misunderstood terms.

Blue Passivate -

Read more

.png)

.png)

Silchrome Plating are proud to be expanding our thriving metal finishing business through the addition of 2 new process workers, at our facility in leeds, West Yorkshire. Morer details below:

Job Title: Process Worker

Job Type: Permanent

Location: Silchrome Plating Ltd, Barras Garth

Read more

.png)

.png)

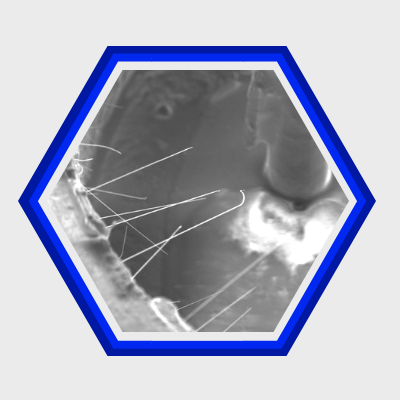

Tin Whiskers are electrically conductive, hair like structures that can grow on surfaces that have been electroplated with pure Tin. This causes failures within electronic components and represents a challenge for manufacturers looking to eliminate lead from production whilst keeping failure

Read more

.png)

.png)

Silchrome Plating are proud to be one of Macdermid’s licensed vendors to carry out Zinc Plating with JS500, here are more details on the advantages of this process.

What is JS500?

JS500 is a water based sealant that can be used as a finishing process in conjunction with Zinc

Read more

.png)

.png)

Silchrome Plating offer a wide array of metal finishing processes, many containing their own subcategories and finishing options. Here is an overview:

Electroplating

The electro-plating process involves taking your component and placing it into a vat/tank containing an electrolytic

Read more

.png)

.png)

Tin Plating To Replace Lead

The Manufacturing industry at large have been looking at the best ways to produce components that are not only fit for purpose but will have as little environmental impact on the earth as possible. RoHS or the Reduction of Hazardous Substances is a directive that

Read more

.png)

.png)

Chemical Blacking is a popular options for customers looking for a matte black finish that will enhance corrosion resistance without causing dimensional changes. Silchrome Plating offer 3 varieties of chemical blacking for different materials.

Also Known As…

Chemical Blacking is a process

Read more

.png)

.png)

Here are some commonly asked questions about plating thickness.

Units

Plating thickness is measured in Micrometres which are commonly referred to as Microns. The symbol for Microns is μm, but it is not unusual for this to be written as um. A micron is one thousandth of a millimetre or

Read more

.png)

.png)

Extending a component’s life span is crucial in any industry, but selecting a metal finishing process is often like opening a can of worms. Not only are there a wide variety of processes to choose from but many have their own sub-categories (3 types of Electroless Nickel for example) not to

Read more

.png)

.png)

A Salt Spray Test accelerates the normal rate of corrosion a component would undergo in order to evaluate the suitability of a protective coating. The appearance of corrosion (such as rust, blisters, peeling) is evaluated after set amounts of time to judge comparatively the effectiveness of any

Read more

.png)

.png)

Metal finishing processes such as Zinc Plating are described as being ‘sacrificial’ in nature, but what does this term actually refer to?

Oxidation

When metals such as Steel are exposed to the elements they will often undergo a process called Oxidation which is corrosive in nature. Iron

Read more

.png)

.png)

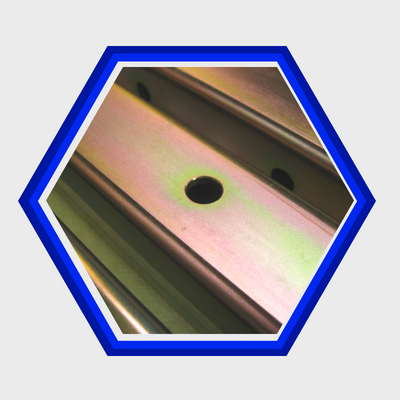

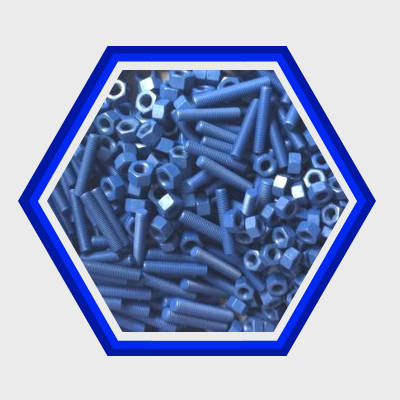

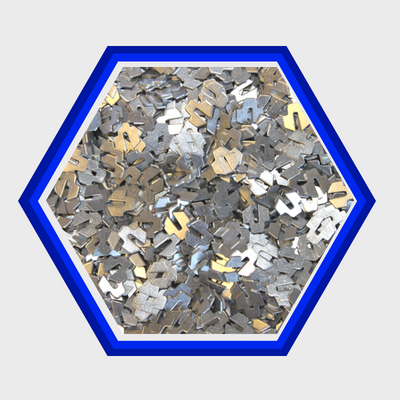

Zinc Plating with Passivate is one of the most popular metal finishing processes for a wide range of components including screws, fasteners as well pressings and automotive components. It is popular for a number of reasons:

Low Cost: Zinc as a material is abundant in nature within the

Read more

.png)

.png)

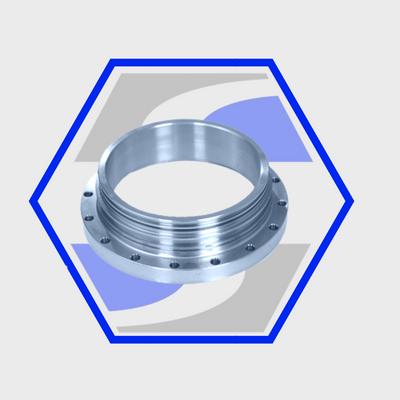

Zinc Electroplating offers a low cost but highly effective way in which to protect ferrous metals against a range of Corrosion sources. So what is Zinc, what can it be used for?

What is Zinc?

Zinc is a naturally occurring element that is abundant in the earth’s crust and is

Read more

.png)

.png)

Silchrome offer a very wide array of metal finishing processes and this includes Paint and Powder Coatings. Our Paint shop has been especially busy of late and so we thought we’d help our customers by giving a quick overview on the information we need to process your enquiry as quickly

Read more

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)