.png)

.png)

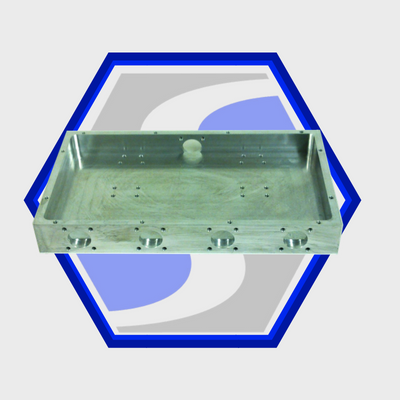

Metal finishing is the process of changing the surface of an object, for the purpose of improving its appearance and/or durability. It is a broad term that encompasses a wide range of different categories, techniques and processes.

The Metal Finishing field can be quite overwhelming for

Read more

.png)

.png)

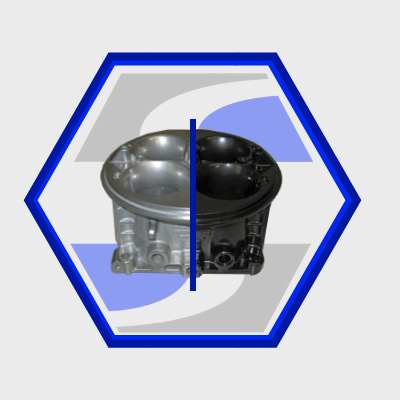

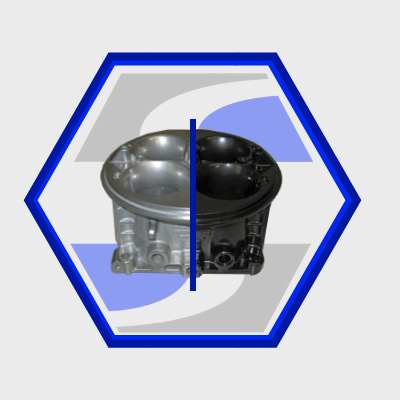

When it comes to producing an aesthetically pleasing matte black finish, the range of options can be quite confusing. Two of the most popular of these processes are Chemical Blacking and Xylan coating, but which process sis better for which situation?

What is Chemical Blacking?

Read more

.png)

.png)

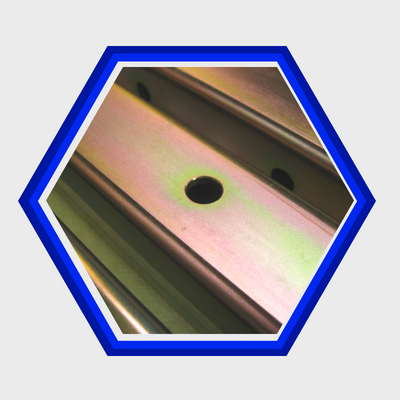

Silchrome Plating are proud to be one of Macdermid’s licensed vendors to carry out Zinc Plating with JS500, here are more details on the advantages of this process.

What is JS500?

JS500 is a water based sealant that can be used as a finishing process in conjunction with Zinc

Read more

.png)

.png)

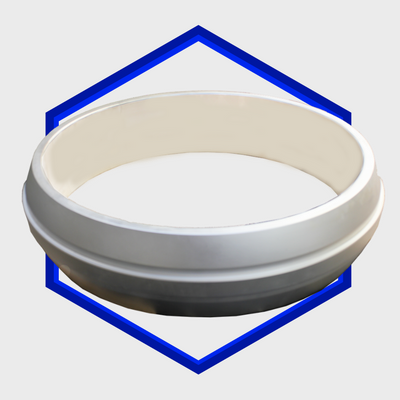

Chemical Blacking is a popular options for customers looking for a matte black finish that will enhance corrosion resistance without causing dimensional changes. Silchrome Plating offer 3 varieties of chemical blacking for different materials.

Also Known As…

Chemical Blacking is a process

Read more

.png)

.png)

A Salt Spray Test accelerates the normal rate of corrosion a component would undergo in order to evaluate the suitability of a protective coating. The appearance of corrosion (such as rust, blisters, peeling) is evaluated after set amounts of time to judge comparatively the effectiveness of any

Read more

.png)

.png)

Metal finishing processes such as Zinc Plating are described as being ‘sacrificial’ in nature, but what does this term actually refer to?

Oxidation

When metals such as Steel are exposed to the elements they will often undergo a process called Oxidation which is corrosive in nature. Iron

Read more

.png)

.png)

Silchrome offer a very wide array of metal finishing processes and this includes Paint and Powder Coatings. Our Paint shop has been especially busy of late and so we thought we’d help our customers by giving a quick overview on the information we need to process your enquiry as quickly

Read more

.png)

.png)

The engineering world is fast paced and competitive with every company looking at ways they can reduce costs whilst still providing high quality goods. One such option is Metal Finishing which encapsulates Plating, Coating, Painting and generally covering a component in another substance.

Read more

.png)

.png)

Aluminium is one of the most widely used materials for a wide number of commercial and industrial applications. This is because it is a lightweight material that can be readily melted, cast, formed and machined into whichever form is required and is 100% recyclable with no downgrading of its

Read more

.png)

.png)

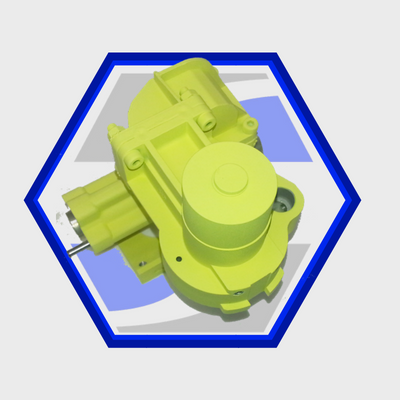

What Is Gleitmo 603?

Gletimo is a family of products produced by Fuchs which encapsulates lubricants, greases, pastes and dry film coatings. Gleitmo 603 is a dry film lubricant which has provides a transparent, touch proof and abrasion resistant layer. It is most often used for the coating

Read more

.png)

.png)

If you have ever worked with or been quoted any sort of metal finishing process then you may have come across the term ‘throwing’ but what exactly does this term mean?

Throwing is short for throwing power. It is defined as the measure of a metal finishing solution’s ability to plate a

Read more

.png)

.png)

Black Oxide Coating, also known as Chemical Blacking is a conversion coating in which a protective barrier is achieved through a chemical reaction between the ferrous metal and the oxidising salts used in the bath. It’s often used on small and intricate moving components in applications

Read more

.png)

.png)

Silchrome Plating are proud to announce that we have been granted ISO 9001:2015 and ISO 14001:2015 certifications. These certifications are a globally recognised Quality Assurance Standard and is a reflection on the processes and procedures Silchrome have in place which enable us to

Read more

.png)

.png)

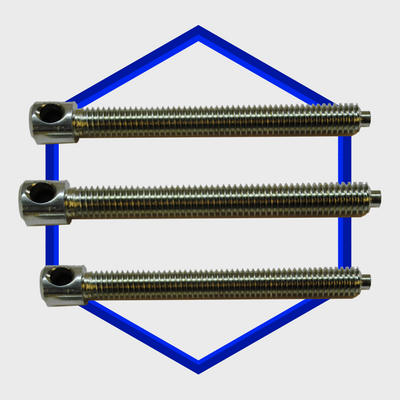

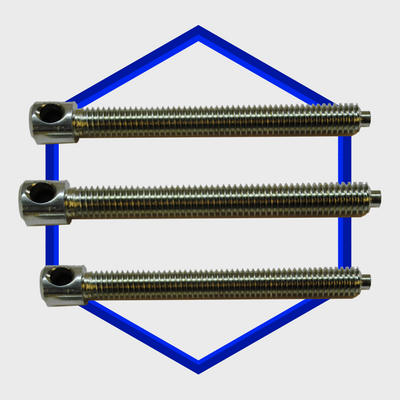

We are all familiar with these small but vital components that literally hold together much of the vehicles, structures and devices that we use every day. Bolts, Screws and Fasteners have a wide variety of applications but often come into contact with dissimilar metals in harsh

Read more

.png)

.png)

A few weeks ago a customer came to us with a number of screws that they wanted to be Chemically Blacked. They were not 100% sure on the grade of material, assuming it was Stainless Steel yet after trying both of our Chemical Blacking processes (for mild and stainless steels) neither would

Read more

.png)

.png)

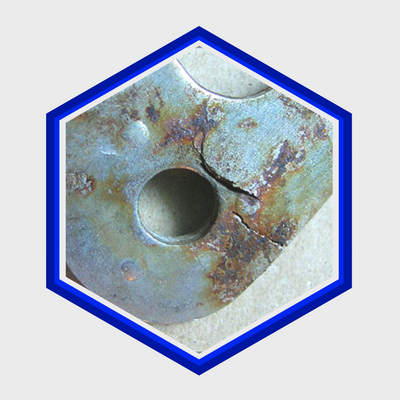

Corrosion is a broad phrase used to describe the attack and deterioration on metals. There are several different types of Corrosion.Here is a broad overview...

General Corrosion

General or Uniform Corrosion is called such as it will proceed in a uniform manner onto an exposed

Read more

.png)

.png)

Silchrome Plating Ltd, the successful Leeds based coatings company are proud to have been added onto the Approved Vendor List for International Oil & Gas provider, Schlumberger and its associated companies Cameron and One Subsea.

The Oil and Gas industries have been through turbulent

Read more

.png)

.png)

Silver is used for its fantastic combination of Electrical and Heat Conductivity alongside it’s Wear and Corrosion resistance. Silver as a material is considered a noble metal generally meaning that it is more resistant to oxidation and other forms of corrosion when compared to other plating

Read more

.png)

.png)

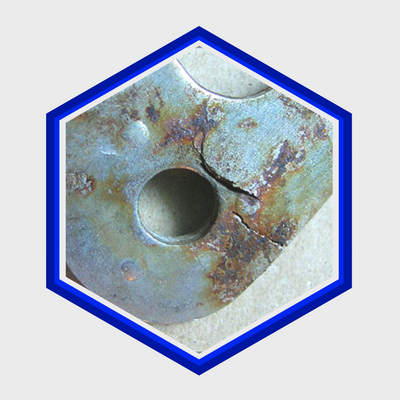

What is Stress Corrosion Cracking?

Where metals are exposed to both tensile stress and a chemically corrosive environment, the growth of crack formations may occur and lead to the sudden failure of normally ductile metals. This may also occur in conjunction with Hydrogen Embrittlement.

Read more

.png)

.png)

Many different components are Zinc Plated in order to improve their part life and enhance their resistance to corrosion. The process, commonly referred to as just ‘Zinc Plating’ is actually short for ‘Zinc and Passivate’ so what exactly is Passivation and why is it needed?

Could You

Read more

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)