Paint & Powder: What We Need To Know

.png)

.png)

Silchrome offer a very wide array of metal finishing processes and this includes Paint and Powder Coatings. Our Paint shop has been especially busy of late and so we thought we’d help our customers by giving a quick overview on the information we need to process your enquiry as quickly as possible. Often on technical drawings a colour may be all that is specified but there is much more to any Paint/Powder Job.

Material

The Material that is being coated will have an impact on the paint we use, certain types of paint are better for certain grades of metal or plastic. The material being used will also have an impact on our process. For example with Aluminium Alloys we will often undergo a layer of Iridite NCP first which acts as a primer for better paint adhesion. Understanding the material and grade is a crucial first step in any Paint/Powder Job.

Application

The next most important is understanding the function the part will take. There are many formulations of paint often with very specific applications so we may be able to recommend a solution to that environment. As an example if your component has an industrial application then it may need a tougher, more wear resistance coating and the colour/finish may be less important. If the component was part of a larger system for example then matching the exact shade with the rest of the part would be a lot more crucial. The environment your component must function will have a big impact on the solution we recommend.

Colour

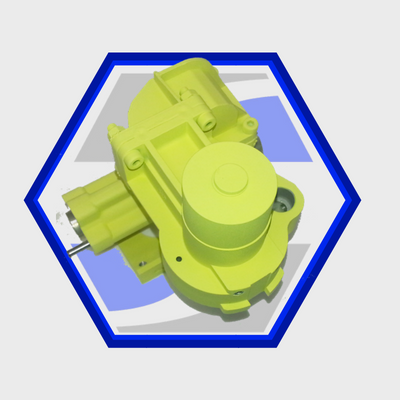

‘Yellow’ is a relatively broad term which many hues, so where you have an application where a very specific colour is needed then understanding this is key. Most often we will use RAL colour charts as a reference where shade is critical, although in the past we have used reference photos of other components and attempted to match the shade.

Sheen

Many of us will be familiar with Sheen from any DIY projects. Sheen is the amount of Gloss which is generally categorised as:

Matte: 1-9% Gloss

Low Sheen: 10-25% Gloss

Eggshell: 26-40% Gloss

Semi-Gloss: 41-69% Gloss

Gloss: 70-89% Gloss

As mentioned before, for industrial applications where the function of the paint is to seal off the component from the environment or for park marking reasons, we may not need to factor this in.

What We Offer

With all of this information above it makes it much quicker and easier for SIlchrome to help you with your Paint/Powder project. We have a number of paints in stock but where you are looking for something specific we can always buy it in. We have invested heavily in new spray facilities and new curing ovens over the last couple of years so you can rest assured your paint job is in the best of hands. Silchrome mostly offer industrial painting for the engineering sector and are fully ISO 9001 and 14001 certified.