.png)

.png)

Metal finishing is the process of changing the surface of an object, for the purpose of improving its appearance and/or durability. It is a broad term that encompasses a wide range of different categories, techniques and processes.

The Metal Finishing field can be quite overwhelming for

Read more

.png)

.png)

.png)

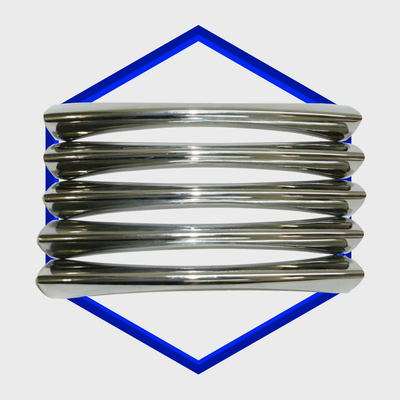

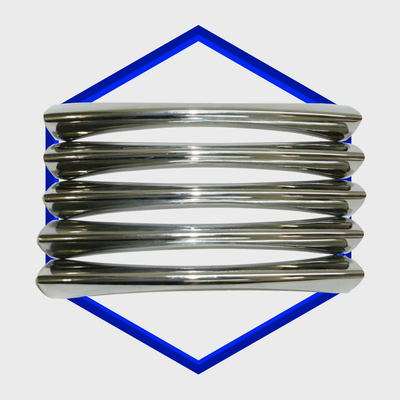

Restoring Chromed items is one of the most common jobs we are asked about here at Silchrome, we often receive enquiries from car enthusiasts looking to restore their pride and joy. Few people understand however that what we simply refer to as ‘Chrome Plating’ actually involves a number of

Read more

.png)

.png)

.png)

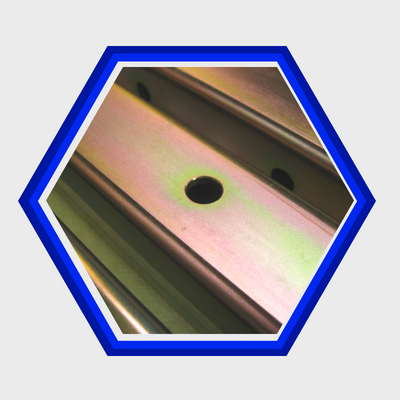

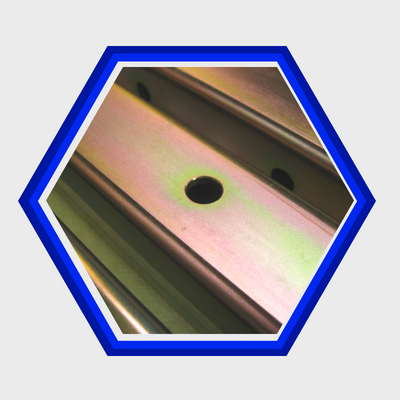

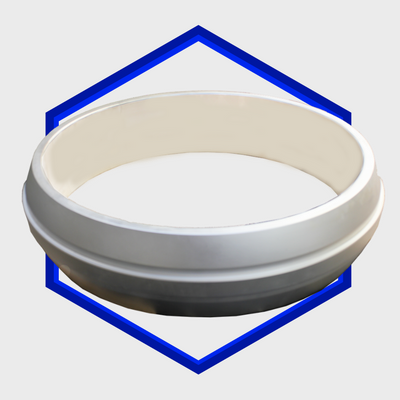

Zinc Plating is always accompanied by a Passivation process which will often have a colour associated with it. The difference between these colours and what exactly they are specifying can be a little confusing so here is a quick guide to some often misunderstood terms.

Blue Passivate -

Read more

.png)

.png)

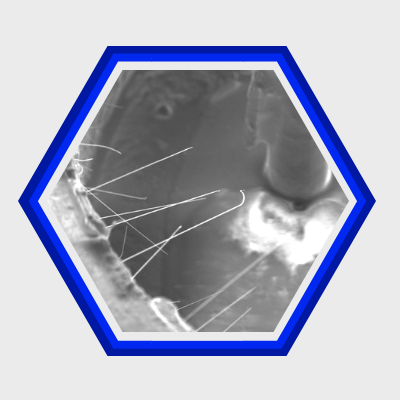

Tin Whiskers are electrically conductive, hair like structures that can grow on surfaces that have been electroplated with pure Tin. This causes failures within electronic components and represents a challenge for manufacturers looking to eliminate lead from production whilst keeping failure

Read more

.png)

.png)

Silchrome Plating offer a wide array of metal finishing processes, many containing their own subcategories and finishing options. Here is an overview:

Electroplating

The electro-plating process involves taking your component and placing it into a vat/tank containing an electrolytic

Read more

.png)

.png)

Tin Plating To Replace Lead

The Manufacturing industry at large have been looking at the best ways to produce components that are not only fit for purpose but will have as little environmental impact on the earth as possible. RoHS or the Reduction of Hazardous Substances is a directive that

Read more

.png)

.png)

Here are some commonly asked questions about plating thickness.

Units

Plating thickness is measured in Micrometres which are commonly referred to as Microns. The symbol for Microns is μm, but it is not unusual for this to be written as um. A micron is one thousandth of a millimetre or

Read more

.png)

.png)

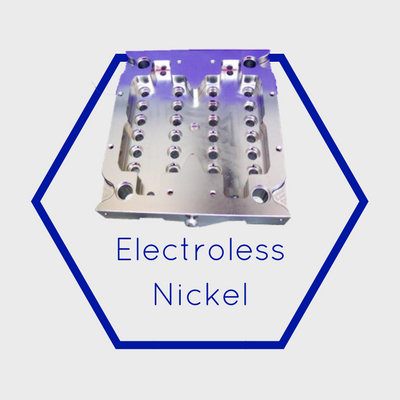

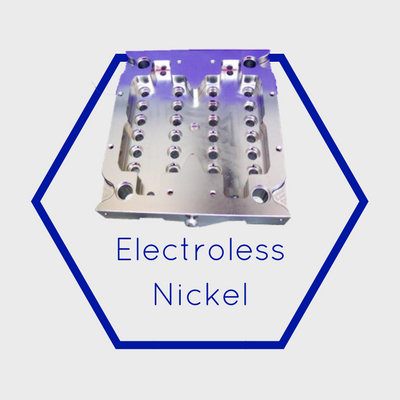

Extending a component’s life span is crucial in any industry, but selecting a metal finishing process is often like opening a can of worms. Not only are there a wide variety of processes to choose from but many have their own sub-categories (3 types of Electroless Nickel for example) not to

Read more

.png)

.png)

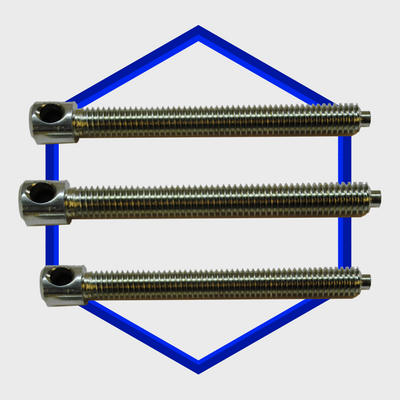

Metal finishing processes such as Zinc Plating are described as being ‘sacrificial’ in nature, but what does this term actually refer to?

Oxidation

When metals such as Steel are exposed to the elements they will often undergo a process called Oxidation which is corrosive in nature. Iron

Read more

.png)

.png)

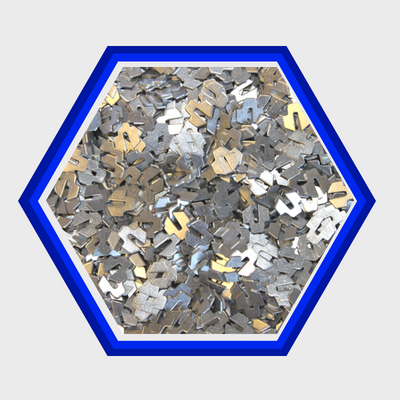

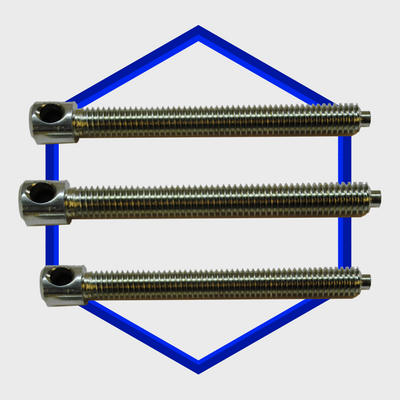

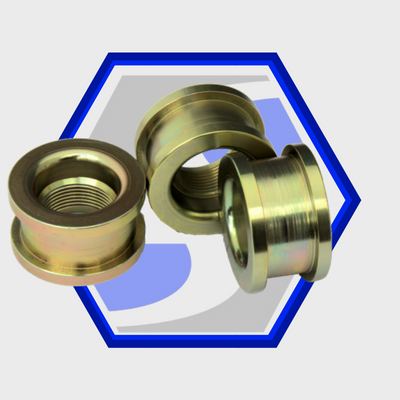

Zinc Plating with Passivate is one of the most popular metal finishing processes for a wide range of components including screws, fasteners as well pressings and automotive components. It is popular for a number of reasons:

Low Cost: Zinc as a material is abundant in nature within the

Read more

.png)

.png)

It is often confusing how one element can have several different plating methods, often sharing a similar name but intended for different purposes. That is certainly the case for Nickel which has a number of distinctly different processes. Nickel Plating is often specified to further enhance a

Read more

.png)

.png)

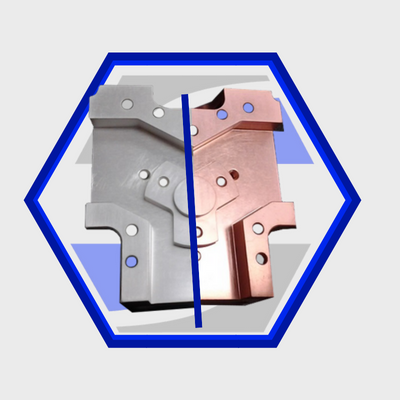

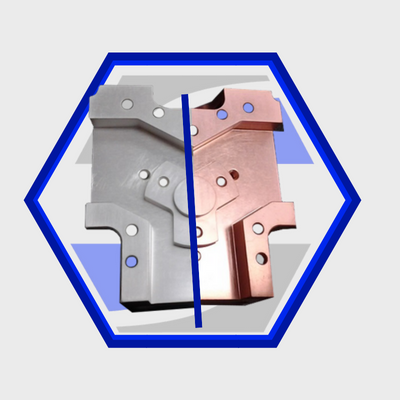

Electro-plated Copper provides excellent thermal and electrical conductivity and is most often used to create a smooth base layer for other metal finishing processes such as Nickel and Chrome. There are a number of different processes in which Copper can be electroplated and Silchrome offer

Read more

.png)

.png)

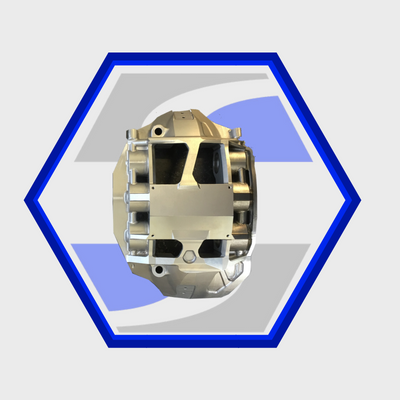

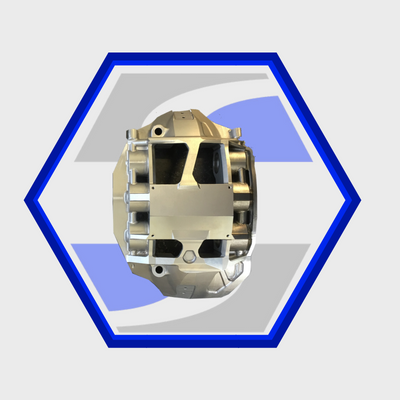

One of Silchrome’s most popular metal finishing processes is Electroplated Chrome. This finish is most noticeable in our everyday lives in ‘Chrome’ Bumpers which are in fact electroplated steel, so what is Chrome, why is it so popular and what is involved in ‘Chroming’ a component?

Chrome

Read more

.png)

.png)

Silver is used for its fantastic combination of Electrical and Heat Conductivity alongside it’s Wear and Corrosion resistance. Silver as a material is considered a noble metal generally meaning that it is more resistant to oxidation and other forms of corrosion when compared to other plating

Read more

.png)

.png)

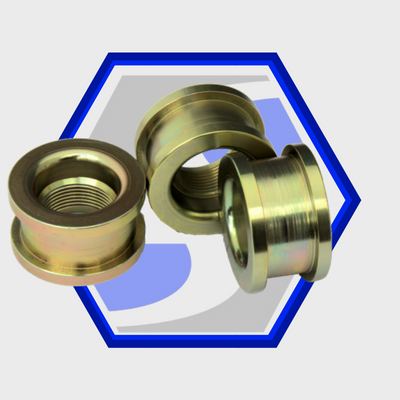

Many different components are Zinc Plated in order to improve their part life and enhance their resistance to corrosion. The process, commonly referred to as just ‘Zinc Plating’ is actually short for ‘Zinc and Passivate’ so what exactly is Passivation and why is it needed?

Could You

Read more

.png)

.png)

Although they both coat the same material, the two different processes will perform differently, have different attributes and different applications.

Nickel Plating provides a low cost, smooth and ductile coating that can be used in variety of applications. It provides a good level of

Read more

.png)

.png)

Silver Plating in the Aerospace Industry

Silver is popular in the Aero-space industry thanks to its ability to reduce the effects of galling (seizure) in high temperatures.

Our aerospace clients will often use Silver plating for their engine fasteners as it will provide a degree of

Read more

.png)

.png)

Silver is widely used across a range of different industries including microwaves, oil and gas and telecommunications, many of us are of course familiar with silver from our jewellery.

Electrical Conductivity

Pure Silver has the highest electrical conductivity of all metals. This

Read more

.png)

.png)

.png)

Silchrome have extensive experience working alongside leading Microwave and RF manufacturers to provide coatings.

When it comes to communication, silver definitely doesn’t mean 2nd best. It’s the most popular plating in the industry. Silver Plating’s key attribute is its electrical

Read more

.png)

People often come to Silchrome looking to restore some life in their bike or car parts through re-chroming but might not understand what’s actually involved with the process. Unfortunately it isn’t as easy as putting your part in the tank and it coming out all shiny and new.

The first step

Read more

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)