Chrome Plating Process

.png)

.png)

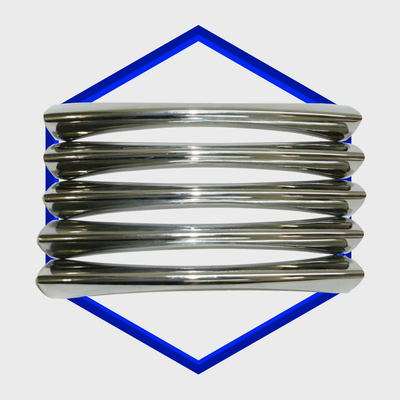

One of Silchrome’s most popular metal finishing processes is Electroplated Chrome. This finish is most noticeable in our everyday lives in ‘Chrome’ Bumpers which are in fact electroplated steel, so what is Chrome, why is it so popular and what is involved in ‘Chroming’ a component?

Chrome Overview

Chrome is short for Chromium and is a naturally occurring element although is not useful in its natural form, so nothing is ever made out of pure Chromium. It is instead Electro-plated onto different metals in two processes referred to as ‘Decorative Chrome’ for applications where an aesthetic finish is more desirable and ‘Hard Chrome’ where a more wear resistant and tough finish is required. Chrome plating will resist oxidation, and increase a components wear resistance whilst retaining a bright finish.

Process

With any sort of metal finishing process, the most important step is often in the preparation of the part. This pre-plating process will vary depending on the condition of the component, the material it is made out of, and also the desired finish. This could include physical preparation such as blasting or polishing, chemical pre-treatments such as pickling as well as water rinsing. The preparation stage is crucial in ensuring the effective bonding of the chrome.

As for the plating process itself, the part once prepared will be placed into a vat/tank containing an electrolytic solution into which a current is run which promotes the build-up of the chrome on the part. The longer the component is in the bath, the thicker this coating will be.

With many decorative finishes (and especially on automobile components) we may first Copper Plate the item so as to create a smooth surface, Nickel Plate it which will enhance its corrosion resistance properties and then Chrome plate it. The amount of Chrome may actually be very small, which differs from Hard Chrome plating where the amount of Chrome will be much thicker.

After this the part may be subject to further treatments which could include polishing. Decorative Chrome Plating can be finished in a range of decorative styles which includes a ‘Bright’ finish which will be shiny and reflective, or for a more textured surface a ‘Brushed’ or ‘Satin’ look could also be achieved and for motorcycle parts in particular a ‘Matte’ or ‘Dull’ finish is often requested which will be non-reflective in appearance.

Silchrome Plating are based in Leeds, West Yorkshire and are a fully ISO 9001 and 14001 accredited metal finisher. We have a wide array of processes all under one roof which includes decorative and hard chrome.