You Asked: How do Passivates protect Zinc Plating?

.png)

.png)

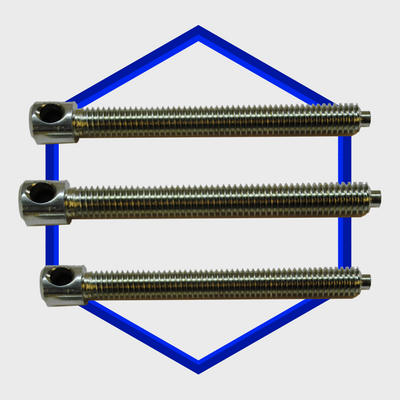

Many different components are Zinc Plated in order to improve their part life and enhance their resistance to corrosion. The process, commonly referred to as just ‘Zinc Plating’ is actually short for ‘Zinc and Passivate’ so what exactly is Passivation and why is it needed?

Could You Just Apply Zinc?

In theory, yes if you wanted to you could just add a layer of Zinc onto your component. The issue is that Zinc in of itself is a very reactive metal and would be susceptible to corrosion in contact with the air and in hot and humid conditions. When Zinc reacts with oxygen it forms Zinc Oxide. When other metals such as Aluminium react with Oxygen this forms a hard and protective oxide layer which is usually desirable, but a Zinc Oxide layer is soft and porous and does nothing to protect the component from corrosion. As such White Rust would form on a component that was purely coated with Zinc.

What Is Passivation?

Passivation is a non-electrolytic process which promotes the build-up of an oxide layer. Now as above Zinc Oxide will not provide corrosion protection. As such the Passivation Process that follows Zinc Plating is a Chromate Conversion and will actually convert the metal surface into a complex mixture of Chromium compounds which will oxidise into a barrier layer. This coupled with the Zinc will provide the desirable attributes of corrosion and wear protection.

Hexavalent and Trivalent

The passivation which is carried out in conjunction with Zinc Plating traditionally utilises Hexavalent Chromium (Cr6), this is a known carcinogen and in order to comply with REACH environmental standards alternatives have had to be developed. As such many Zinc Plating passivates will now instead utilise Trivalent Chromium (Cr3) which addresses these environmental concerns. At present Silchrome are still offering both Hexavalent and Trivalent based Passivates, but in the future we may only be able to offer Trivalent. For more information on the differences between the two, why not read our article HERE.

Silchrome Plating carry out a wide range of processes from our production facility in Leeds, West Yorkshire and are fully ISO 9001 and 14001 accredited.