How Metal Finishing Reduces Manufacturing Costs

.png)

.png)

The engineering world is fast paced and competitive with every company looking at ways they can reduce costs whilst still providing high quality goods. One such option is Metal Finishing which encapsulates Plating, Coating, Painting and generally covering a component in another substance. This can save you manufacturing costs in a number of ways:

Extending Part Life

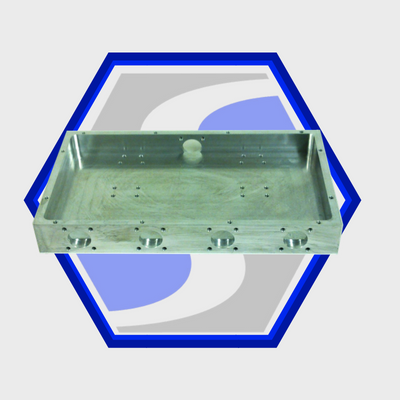

The cost of replacement and re-manufacture of any component can be significant and so any method in which a component’s life cycle can be extended will always save money. Metal Finishing has long been used to encapsulate the base material from its environment and increase its resistance to oxidation, wear and corrosive damage. There are a wide variety of different processes which will suit different materials and different applications but one example of this would be Anodising which is often used to extend the naturally occurring oxide layer of Aluminium components to further protect the component.

Cheaper Base Materials

Rather than manufacturing something out of Gold or Silver, Metal Finishing has long been used to add a layer of this material to a cheaper base material such as Steel. Not only does this represent significant savings when compared to manufacturing out of these precious metals but also allows you to give their desirable attributes to a cheaper material.

Ease of Manufacture

In many cases it is quicker and easier to use Metal Finishing to give a component the desirable attributes of another metal. For instance Copper is a relatively soft and ductile metal and may be difficult to form complex shapes without breakage, but can be readily applied to a complex geometry through electro-plating. Another example of this would be Iridite NCP which is often used to form a base for painting, creating better adhesion for the paint and saving costs as fewer layers of Paint will then be needed.

Application Specific

Metal finishing is ever changing and where some processes have remained more or less the same for hundreds of years, new and exciting technology is developing for very specific applications. As an example Xylan 1052 is formulated to prevent wear on mating surfaces where Xylan 1400 is much more of a barrier coating for fasteners and threaded parts. We expect more niche coatings to be developed in reponse to the global effort to use resources more wisely and extend component lifespan.

Silchrome Plating offer a wide array of Plating, Coating, Anodising, Pianting, Phosphating and more. We are fully ISO 9001 and 14001 certified and all of our processes are carried out from our modern facility in Leeds, West Yorkshire.