Repairing Chromed Items

.png)

.png)

One of the most common enquiries we receive at Silchrome is that of repairing worn/damaged chromed items which can include anything from car bumpers through to bathroom fittings. Here is an overview on what issues re-plating can solve and potential costs.

What Issues Can Re-Plating Solve?

When it comes to any kind of restoration, no two components are the same and so what follows it a broad guide as to the issue sand problems that re-plating your part may solve.

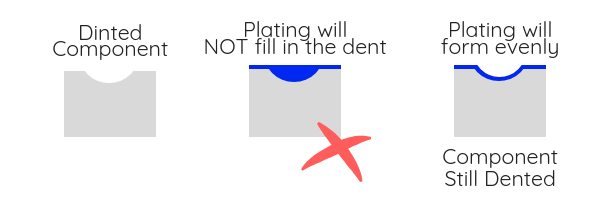

Scratches: One of the most common misconceptions about plating is that where you have a crack, the material will pour into in and fill it up in much the same vein that you might use Poly-Fitter to fill in a crack in the wall. The reality is that most Plating will add an even amount of material onto a part so the dint/scratch will remain a dint after plating. As such any Dints or Scratches would need to be smoothed either through chemical or mechanical means. We will strip away any existing plating and then may need to grind/polish the component so as to ensure there is a smooth surface for plating.

Rust: Where you have points of corrosion, these will also need to be removed before re-plating. It isn’t a case that you can just re-plate an item and it will be good as new. The rust will still attack the base metal underneath the plated area. Depending on the severity of the rust we may need to strip away and chemically or mechanically remove the rusted areas. Where a component has suffered particularly bad damage it may not be possible to repair it and you may need to buy a replacement.

Flaking Chrome: Over time, Chrome Plating may flake or peel off. This is certainly an issue that re-plating can solve. Even if only a small area has peeled off, it is most likely that we will need to remove all of the Chrome on the part, most often this is done through a chemical process which will not damage the base metal.

Dull Chrome: Where a part is not damaged but the finish has begun to Dull it may be possible to restore the shine through polishing or electro-polishing and re-chroming it may not be needed. Sometimes Dull Chrome is the result of wear or corrosion on the part and may actually be a sign of damage, and in these cases re-chroming may be the better option.

Potential Costs: The process of re-chroming an item actually involves several stages including pre-plating, copper plating, nickel plating, chrome plating and then polishing. As such in many cases it may be more cost effective to buy a replacement part. Our minimum charge is £60+vat so where you have items such as bathroom fittings or decorative items it may not be worth the cost of re-chroming.

Silchrome Plating are an ISO 9001 and 14001 metal finisher who offer a wide variety of metal finishing processes including electro-plating, painting and much more. We carry out all over processes from our modern facility in Leeds but deliver across the country.