How Plating Affects Dimensions

.png)

.png)

Here at Silchrome we are often asked the impact that a metal finishing process will have on the dimensional tolerance of a component. Here is a broad overview we hope will answer many of your questions.

Amount Added

Most metal finishing processes such as electro-plating or paint and powder coating will be adding an amount of material above the surface they are being applied to. There is a category of processes which are a little different called Conversion Coatings, here instead of adding a layer of material the surface is being converted into something else. These types of coatings will most often form above and below the surface. A good example of this would be Anodising. Where 10 microns of Anodising is specified half of this will be below the surface meaning around 5 microns will be added.

Uniform Thickness

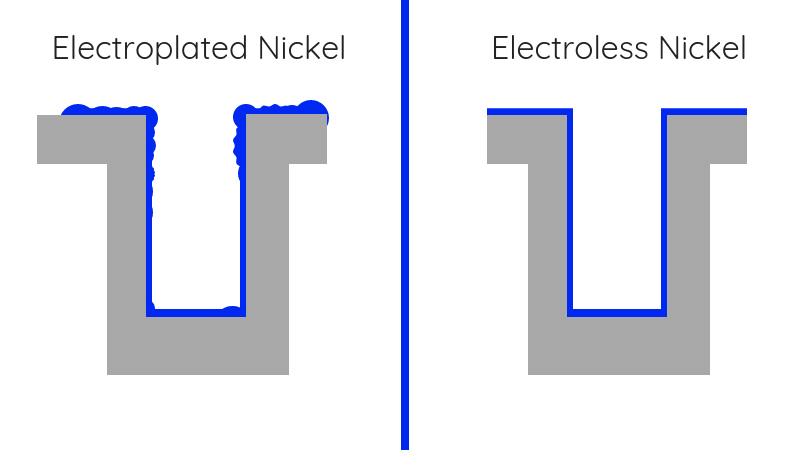

With most metal finishing processes it is both normal and unavoidable to have a small amount of variation in thickness. When a thickness is specified it will most often be within a range, for example 2-5 microns. This range means that on no part of the finished area should fall under 2 microns thick or over 5 microns thick but different areas may fall within that range. Some processes such as Electroless Nickel will form a uniform thickness no matter the surface they are applied to, but most will form with more material on edges and less in crevices. (See picture)

Complex Geometry

A complex component represents a challenge for any metal finishing process and especially in electro-plating where flat and recessed areas will create high and low density zones which will result in thicker and thinner plating plating areas. The variation in thickness will only be a few microns and just to give you an idea of just how small that is 7 microns is about the size of a red blood cell and 2 microns is the size of a bacteria. At these sort of sizes it is unlikely that any variation in thickness will affect the effective use of a given component and would probably have less impact then metal contracting/expanding with temperature.

Silchrome Plating offer a wide range of metal finishing processes including electroplating, anodising, paint and powder coating and many more. We are fully ISO 9001 and 14001 certified and carry out all our processes from our modern facility in Leeds,West Yorkshire.