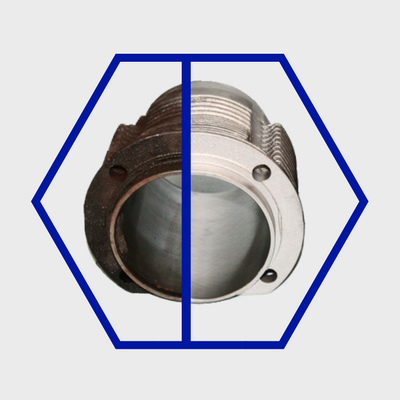

Complex Cast Iron Plating

Cast parts represent a challenge to most metal finishing companies. Cast parts are prone to having rough surfaces of a non-homogenous nature and often contain a high carbon content, impurities and various residues. This means in order to ensure a high quality finish he right selection of pre-treatment and plating knowledge is key.

Pre-Treatment

The first stage when effectively pre-treating cast parts is to remove anything on the surface which might affect plating. In some cases Cast materials may come oiled, in order to avoid contamination during the plating stage, we must completely remove any oil. The same is true of any sand, rust or carbon residues which may sit on the surface of Cast Parts.

Most often we will use an alkaline solution in order to chemically clean the parts, but any acid pickling process is usually kept as short as possible. This is because strong acid pickling will actually enrich the carbon found at the surface and can interfere with the plating process.

Plating

There are a number of different processes which can be applied to Cast Parts.Some of the more popular include:

Zinc – Zinc plating of cast parts is an especially popular process with brake components. Zinc plating helps form a protective barrier against rust and other forms of corrosion, and being relatively inexpensive in comparison to other processes, is suitable for high volume production.

ENP – Electroless Nickel Plating offers a smooth and uniform finish which is ideal for complicated cast parts. Depending on the environment in which the part needs to function different levels of phosphorus can be used in the solution. The higher the phosphorus content, the higher the corrosion protection afforded. Electroless Nickel Plating meets ROHS and WEEE requirements and unlike Hard Chrome which tends to soften at high temperatures, ENP is suitable for heat treatment further increasing hardness.

Hard Chrome – Hard Chrome is often used in extreme environments such as Oil and Gas. As its name suggests it will increase the hardness of a component as well as offering excellent corrosion protection. In order to achieve a strong bond, often cast iron components will be first coated with Nickel to form a smooth base for the Chrome. One of the key benefits of this process is the ability to build up many layers of coating.

What We Offer

Silchrome Plating offer one of the widest arrays of metal finishing processes across the UK. We have extensive experience in the plating of a wide range of materials including cast parts. All of our processes are carried out in our production facility in Leeds, West Yorkshire. We are fully ISO approved.