Electroless Nickel: Applications In Industry

.png)

.png)

Electroless Nickel provides a uniform coating that will increase wear and corrosion resistance of Brass, Aluminium and Steel components. The versatility of the process and the ability to change the phosphorus content to suit your application makes Electroless Nickel a popular process across several industries.

Oil & Gas

Oli and Gas components need to be able to perform for a long period of time under often extreme conditions. These components could be exposed to Chlorides, Carbon Dioxide, Brines, Sea Water, Reef Water as well as Hydrogen Sulphide. In some cases components must function at high temperatures and may be subject to wear through sand or mud. components within the Oil & Gas industries. These include: Brake Assemblies, Gas Turbines, Chokes, Compressors, Heat Exchangers, Pumps.

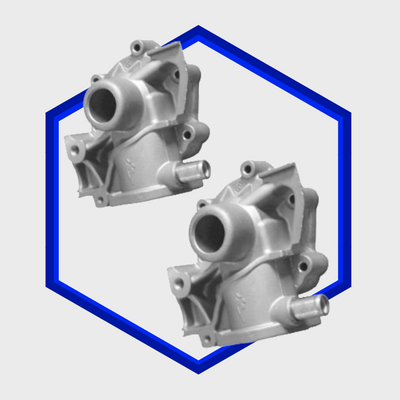

Automotive Industry

Automotive companies have been refocusing on fresh, innovative ways in which to improve part life and performance. A large part of this work has been the introduction of new engines and new fuels and as such they have had to think of new ways to protect parts and increase life cycle. Components in the Automotive Industry are often small and intricate in nature and so one major challenge that ENP addresses is uniformity of coating. Electro-deposited coatings will often build up around the edges, whereas Electroless Nickel is able to form an even coating, even where there are uneven surfaces. Electroless Nickel would be suitable for: Carburetor, hose couplings, engine bearings, pistons, heat sinks, fuel injectors, Gears, Shock Absorbers, Cylinders and more.

Chemical Processing

A key consideration for the Chemical Processing Industry is finding a way to extend equipment life without affecting the purity of the product. The autocatalytic nature of Electroless Nickel and its ability to protect against a wide variety of chemically corrosive sources. Electroless Nickel is suitable for use in protection against a wide range of different chemicals. These include Sodium Hydroxide, Phosphorus Oxychloride, Benzoyl Chloride, Benzitrichloride, Phosphoric Acid and many more. Minimum Thickness is typically recommended at 40 microns but for more corrosive environments 75 microns may be better suited.

The Food Industry

The most common material found in any Food Processing Equipment is Stainless Steel. In recent years as cost saving has taken precedent a number of alternative materials have been trailed including Aluminium Alloys and Carbon Steel. When these materials are used they will most often require a protective barrier and Electroless Nickel has gained wide acceptance in this area. High Phosphorus Electroless Nickel is the most popular with the Food Industry on components which may be subject to a wide variety of Acids most noticeably Citric, Lactic, Phosphorus and Acetic Acids. Parts that can benefit from Electroless Nickel Plating would include: Bearings, Rollers, Conveyor Systems, Gears, Mixers and many more.

Silchrome Plating provide both Medium and High Phosphorus Electroless Nickel and carry out all our processes from our modern production facility in Leeds. We are fully ISO 9001 and 14001 certified and serve the whole UK.