.png)

.png)

Metal finishing is the process of changing the surface of an object, for the purpose of improving its appearance and/or durability. It is a broad term that encompasses a wide range of different categories, techniques and processes.

The Metal Finishing field can be quite overwhelming for

Read more

.png)

.png)

Silchrome Plating offer a wide array of metal finishing processes, many containing their own subcategories and finishing options. Here is an overview:

Electroplating

The electro-plating process involves taking your component and placing it into a vat/tank containing an electrolytic

Read more

.png)

.png)

It is often confusing how one element can have several different plating methods, often sharing a similar name but intended for different purposes. That is certainly the case for Nickel which has a number of distinctly different processes. Nickel Plating is often specified to further enhance a

Read more

.png)

.png)

We recently had a customer who was concerned about the porosity of an Electroplated Nickel finish for an application within the marine industry. So what is porosity, why is it undesirable and what is the best finish to combat against this?

Porosity is the measure of small voids/pours within

Read more

.png)

.png)

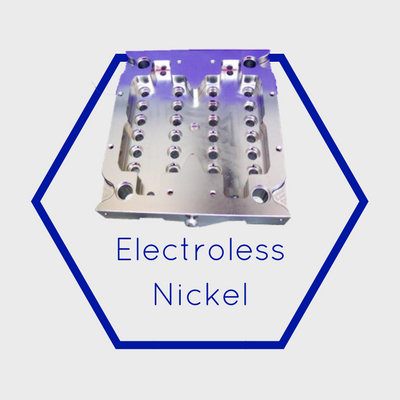

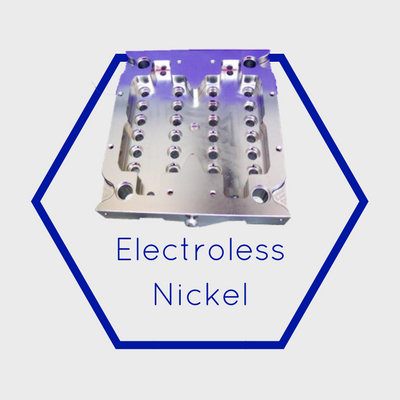

Silchrome have a comprehensive guide to Electroless Nickel including it's attributes and applications.

ENP is a very versatile process that can add corrosion resistance to a variety of components, by changing the Phosphorus content you can better adapt the process to your appllication

Read more

.png)

.png)

Electroless Nickel provides a uniform coating that will increase wear and corrosion resistance of Brass, Aluminium and Steel components. The versatility of the process and the ability to change the phosphorus content to suit your application makes Electroless Nickel a popular process

Read more

.png)

.png)

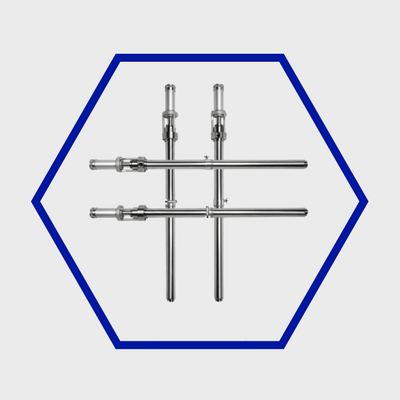

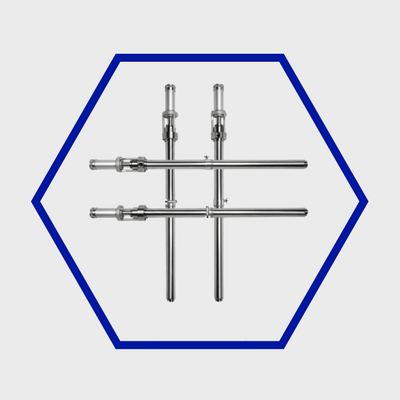

Silchrome Plating Ltd, the successful Leeds based coatings company are proud to have been added onto the Approved Vendor List for International Oil & Gas provider, Schlumberger and its associated companies Cameron and One Subsea.

The Oil and Gas industries have been through turbulent

Read more

.png)

.png)

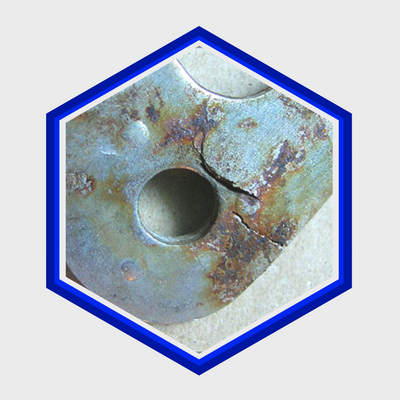

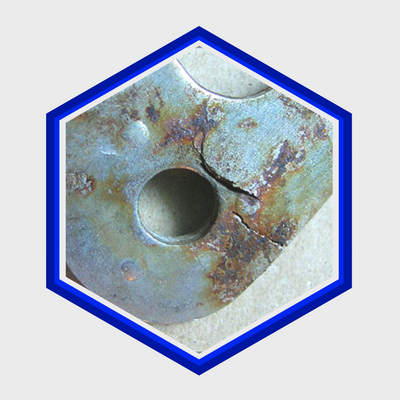

What is Stress Corrosion Cracking?

Where metals are exposed to both tensile stress and a chemically corrosive environment, the growth of crack formations may occur and lead to the sudden failure of normally ductile metals. This may also occur in conjunction with Hydrogen Embrittlement.

Read more

.png)

.png)

Electroless Nickel Plating is a very versatile process that can increase the corrosion resistance of a variety of components. These are the advantages of using it in food processing applications.

Material Replacement

The most common material found in any Food Processing Equipment is

Read more

.png)

.png)

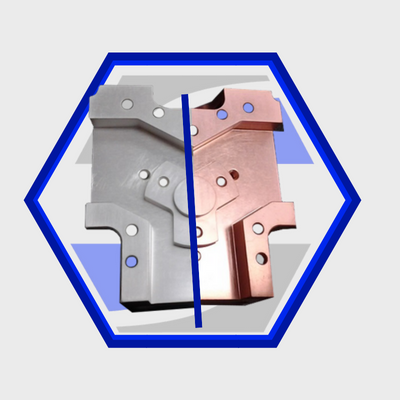

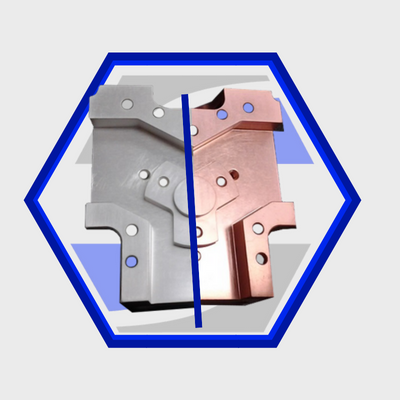

Although they both coat the same material, the two different processes will perform differently, have different attributes and different applications.

Nickel Plating provides a low cost, smooth and ductile coating that can be used in variety of applications. It provides a good level of

Read more

.png)

.png)

.png)

The short answer is yes. Most common grades of Stainless Steel can be reliably Chrome Plated, this may however not be the most appropriate process depending on your application.

For A Bright, Shiny Finish

For decorative applications, it may be simpler to instead Electro-polish the item

Read more

.png)

.png)

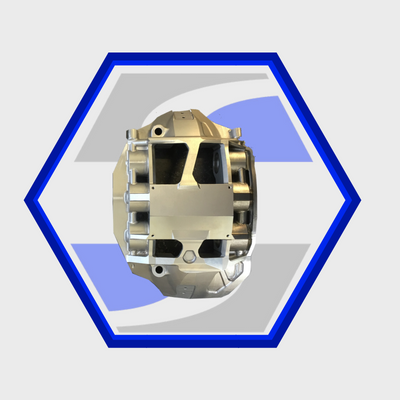

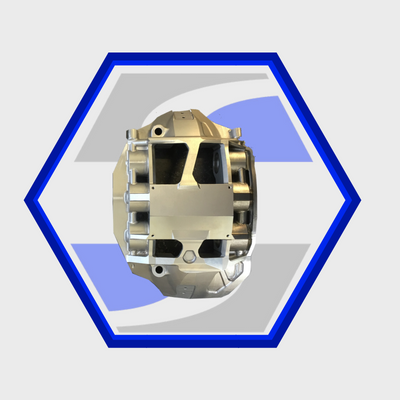

Corrosion costs the Oil and Gas Industry billions each and every year and any component which operates in an offshore environment must withstand several different sources of deterioration. These include the salt water environment, numerous sources of wear as well as potential chemical and gases

Read more

.png)

.png)

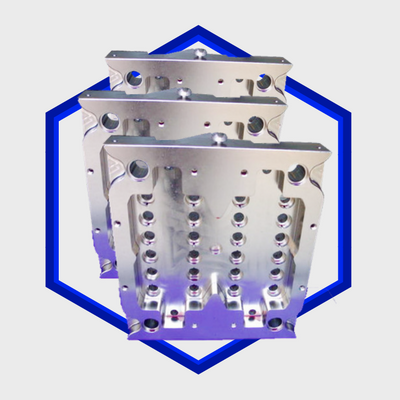

A key consideration for the Chemical Processing Industry is finding a way to extend equipment life without affecting the purity of the product. Electroless Nickel is a conversion coating that is able to form a protective barrier for a range of parts. One of the great advantages of the process

Read more

.png)

.png)

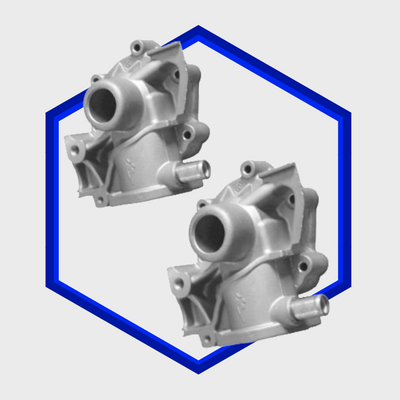

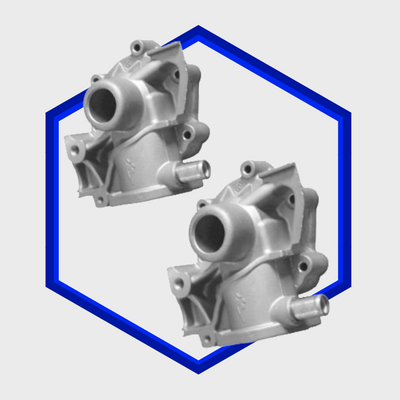

Automotive companies have been refocusing on fresh, innovative ways in which to improve part life and performance. A large part of this work has been the introduction of new engines and new fuels and as such they have had to think of new ways to protect parts and increase life cycle. The

Read more

.png)

.png)

.png)

Electroless Nickel is widely used throughout the Oil and Gas Industry due to its uniform coating, excellent corrosion resistance and ability to act as a protective barrier against abrasion. There are three key areas in which Oil and Gas components must operate: Surface Operations, Downhole

Read more

.png)

.png)

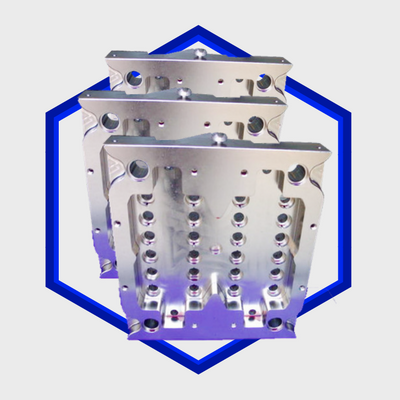

Attributes of Electroless Nickel

Electroless Nickel Plating (or ENP for short) is an autocatalytic plating meaning that it forms through a chemical reaction to the metal. It’s used across a wide range of industries due to its core attributes of corrosion and wear resistance.

Uniform

Read more

In the last four years Silchrome Plating have been investing heavily in order to upgrade our service and offering and make us more efficient. One area that directly benefits our customers is our investment into new processes. With any new process it’s important for us not only to ensure we

Read more

.png)

.png)

.png)

Silchrome Plating are excited to enter the New Year with fresh dedication to being your number one source for metal finishing services. This includes electo-plating, conversion coatings and paint and powder coating.

We provide all of our services in house at our production facility

Read more

.png)

Electroless Nickel Plating or ENP provides fantastic corrosion resistance properties to your component.

High Temperature

ENP has a high melting point of 890 degrees (1630 Fahrenheit) and performs extremely well in high temperature oxidizing environments. For example in steam, air and

Read more

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)