Electroless Nickel In Food Processing

.png)

.png)

Electroless Nickel Plating is a very versatile process that can increase the corrosion resistance of a variety of components. These are the advantages of using it in food processing applications.

Material Replacement

The most common material found in any Food Processing Equipment is Stainless Steel. Although 316 is most commonly referred to as being the ‘Food Grade’ a number of different Stainless Grades are used throughout the industry. In recent years as cost saving has taken precedent a number of alternative materials have been trialed including Aluminium Alloys and Carbon Steel. When these materials are used they will most often require a protective barrier and Electroless Nickel has gained wide acceptance in this area. (Although Electroless Nickel can also provide added protection to Stainless Steel too.)

Applications

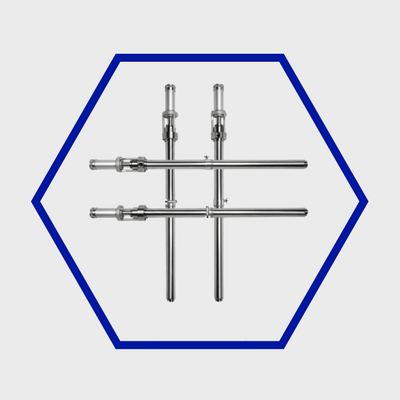

Parts that can benefit from Electroless Nickel Plating would include: Bearings, Rollers, Conveyor Systems, Gears, Mixers and many more.

Low, Medium or High?

One of the great advantages with ENP is the ability to adjust the Phosphorus content to suit your applications. A Low Phosphorus Deposit will be better at combating Alkaline Chemicals. A Medium Phosphorus will be better at combating Acidic Chemicals and provides a good level of wear resistance. High Phosphorus provides the best level of corrosion protection, most noticeably against Acids but also against a wider range of corrosion sources than the other two. It’s this reason that make it the most popular within the Food Industry. Components which may be subject to a wide variety of Acids most noticeably Citric, Lactic, Phosphorus and Acetic Acids.

Uniformity

One of Electroless Nickel’s main selling points is that it provides an even coating on uneven surfaces. Unlike in electroplating where a layer is added on top which will often build up around the edges, ENP is an autocatalytic conversion where the Nickel in the bath acts as a catalyst for the plating reaction and forms a deposit with a high degree of thickness uniformity no matter the shape of the component.

Applications

Electroless Nickel is a very versatile coating that offer excellent corrosion protection and when heat treated can reach hardness levels estimated to be around 90% of Hard Chrome. One area in particular where ENP has been proven effective has been Meat Processing. In this environment components are likely to encounter Sodium Chloride, Citric Acid, Wood Smokes, Humid Atmospheres and High Temperatures and so Electroless Nickel provides a good finishing options to combat these factors.

For all your metal finishing needs, Silchrome are ISO 9001 and 14001 accredited and all of our processes are carried out in house at our production facility in Leeds.