Corrosion Resistance of Electroless Nickel

.png)

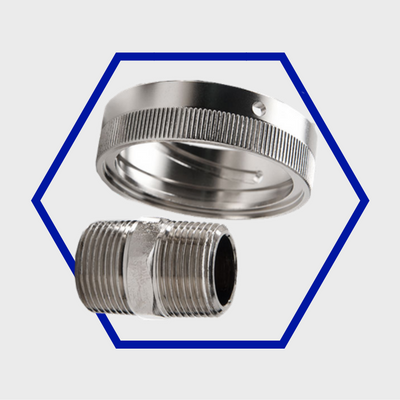

Electroless Nickel Plating or ENP provides fantastic corrosion resistance properties to your component.

High Temperature

ENP has a high melting point of 890 degrees (1630 Fahrenheit) and performs extremely well in high temperature oxidizing environments. For example in steam, air and flue gases. Where ENP is exposed to environments containing sulfur at temperatures over 275 degrees (525 Fahrenheit) sulfidation may occur.

Sea Water

Where components might be exposed to seawater spray then any metal can experience a level of corrosion. ENP offers fantastic protection against this and components will be fully protected by a 3 mil (75µm) thick Electroless Nickel deposition.

Petroleum

Electroless Nickel Coatings are very popular with the petroleum industry. This is because they can stand up to the wide range of factors that might cause corrosion in that environment including: salt water, oxygen, nitrogen, acids and more.

Capability

Silchrome offer Electroless Nickel Plating in both Medium and High Phosphorus. We can perform the process on Brass, Steel and Aluminum components. We can plate components up to 2000mm in length and 100kg in weight but for the general production the plating window is 1000mm x 600mm x 600mm.

Get in touch today to see how Silchrome can help add corrosion resistance properties through Electroless Nickel Plating.