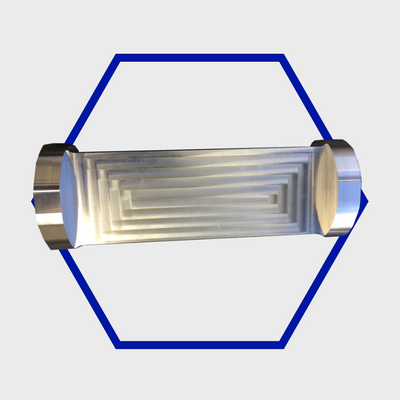

What is electro-polishing?

.png)

.png)

What is electro-polishing?

In the electro-plating process, the metal components is fitted with two electrodes and connected to a power supply. This is immersed into a specially formulated, temperature controlled electrolytic solution. During the process, surface impurities and irregularities are removed and oxidation of the metal surface occurs.

What are the Benefits?

Decorative- As you might imagine with any kind of polishing, this process will brighten the metal finish of your component. It will also minimise stains and heat discoloration as well as minor scratches.

Surface Prep- In creating a smooth, clean surfaces, parts are properly prepped for plating and adhension is promoted. With many of the parts that Silchrome plate, we will already highly polish them before plating.

Corrosion Resistance- You might not expect that electro-polishing your component may also improve its corrosive resistance. By eliminating the imperfections on the metal, moisture is prevented from accumulation.

Microfinish- Electropolishing can effectively remove microscopic peaks that result from processes such as welding, forming and stamping. This can be extremely beneficial to the production of valve and gear components.

Get in touch today and see how Silchrome can provide a cost effective electro-polishing service with a fast lead time.