Anodising to prevent Galvanic Corrosion

.png)

.png)

What is Galvanic Corrosion?

Galvanic corrosion occurs when two dissimilar metals come into electrical contact. This can often lead to deterioration in one of the metals even where the component is operating in an environment that would normally not be considered corrosive.

What is Anodising?

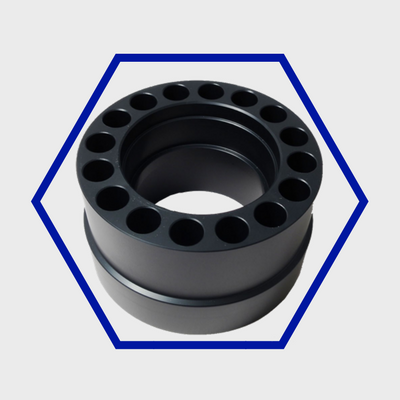

Anodising is a conversion coating which coats an Aluminium part with a protective oxide layer. As a conversion coating, anodising develops both inwards and outwards from the original material surface. This means it has an incredibly high bond strength and won’t flake off in the way that painting might. This creates a layer of Aluminium Oxide which acts as a protective barrier from corrosion.

How does It Work?

The layer of Aluminium Oxide that is formed during Anodising is an insulator and not a metal and is therefore compatible with other common metals by virtue of being non-conductive.

Types of Anodising

Silchrome Plating offers two main kinds of Anodising. Sulphuric Anodising (which is also called Natural Anodising) will give Aluminium components protection against corrosion as well as offering electrical insulation and increased hardness. If your component is expected to perform in an environment with high wear then Hard Anodising might be right for you. Hard Anodising offers increased wear, heat and corrosion resistance and depending on the alloy chosen can be built up to 100um thickness.

Specs Offered

SIlchrome can anodise to Def Stan 03-25 and BS EN 12373-1, which replaced BS 1615.

Get In Touch

Get in touch with Silchrome today. All of our processes are carried out in house in our production facility in Leeds, West Yorkshire. We strive to provide excellent service, fast lead times and a high quality product to each and every customer.