3 Types of Phosphating

.png)

.png)

Phosphating is a conversion coating applied to Steel and Iron components. In its basic form, the process involves immersing a component in a dilute solution, which converts the surface of the metal into a layer of microscopic Phosphate Crystals. The crystalline nature of this coating retains oil and provides a 'foothold' for paint and so is most often used as a pre-treatment process. The 3 varieties of Phosphating are Iron, Zinc and Manganese and the distinction is indicative of the crystals that are formed with each.

Iron Phosphate

Iron Phosphating will increase paint adherence and impact resistance as well as provide protection against oxidation. It offers the least corrosion resistance of the phosphating processes but due to its low cost is often used on indoor equipment and other parts which will not be subjected to high levels of wear and corrosion. The colour of the deposit will differ depending on the weight of the coating ranging from a pale blue in a light deposit to a grey colour for a heavy deposit.

Manganese Phosphate

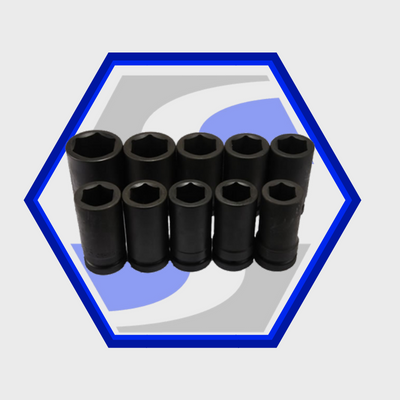

As with all Phosphate processes the primary application is as an undercoat for lubricants or paint. Manganese Phosphating is perhaps the most absorbent of the three processes and is often used as a carrier for rust inhibiting oils and waxes. It is primarily used as a means to prevent metal on metal contact. Manganese Phosphate is generally more corrosion resistant and then Iron Phosphate and is also more stable than Zinc under higher pressures and temperatures. It is the most wear resistant of the three, but not as corrosion resistant as Zinc Phosphate. Manganese Phosphating will prevent galling without the coating flaking or peeling off and is popular in the automotive and power transmission industries. In terms of colour, Manganese Phosphate is a dark grey, near black.

Zinc Phosphating

Zinc Phosphating is primarily selected for corrosion protection of ferrous metals. Zinc Phosphate is suitable for hard weather applications and is most popular in the automotive industry. Similar to the other processes, Zinc Phosphate will inhibit galling and increase lubricity as well as acting as a carrier for paint, oils and waxes. Visually, Zinc Phosphating will be a dark shade of grey, although can be dyed to provide a matte black finish.

Silchrome Plating provide a wide range of conversion coating which includes Iron, Manganese and Zinc Phosphate finishes. We are fully ISO 9001 and 14001 certified and carry out all our processes from our modern facility in Leeds, West Yorkshire.